Are you saying the citizens of Berkeley are Communists, reminiscent of those on the dark side of the Iron Curtain?

There are probably more Communists in Berkeley than any other town in America, but I think of them more as lovers of Birkenstocks than Marx.

--- John Yoo on the constant protests by the vapid at Berkeley. Actually is a pretty funny guy: http://www.nytimes.com/2010/01/03/magazine/03fob-q4-t.html?partner=rss&emc=rss

A collection of posts often on colt E- and I-frame revolvers: pythons, model 357s, officer model specials, etc. Topics not limited to: action jobs, fixing Bubba-gone-wrong gunsmith mistakes, and revolver porn. And sometimes I'll wander off the reservation and type random nouns and verbs that have nothing to do with our sole purpose, because who the hell can really pay attention that long?

Tuesday, December 29, 2009

#1 ranked chess player is 19

I've not followed chess in a long time, other than Fischer's japes and Kasparov's opera, so totally missed this the fact that the #1 ranked player is 19. Interesting (albeit old) interview here when he was 13: http://www.chessbase.com/newsdetail.asp?newsid=1614

Labels:

not-blam

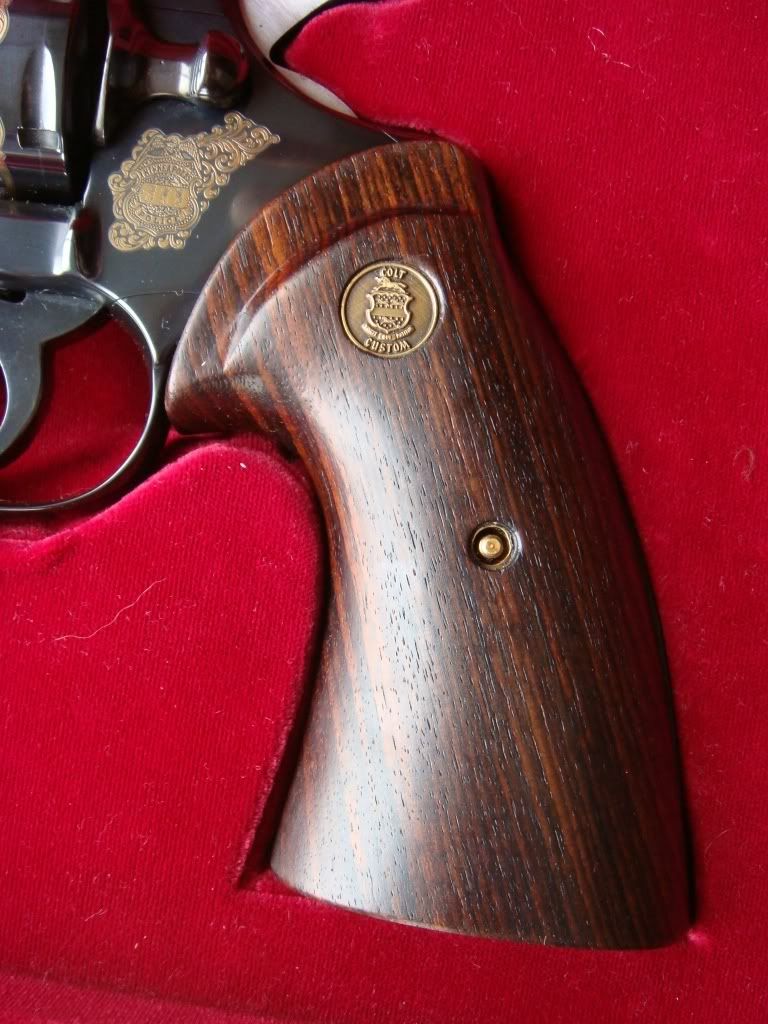

Some (colt) porn

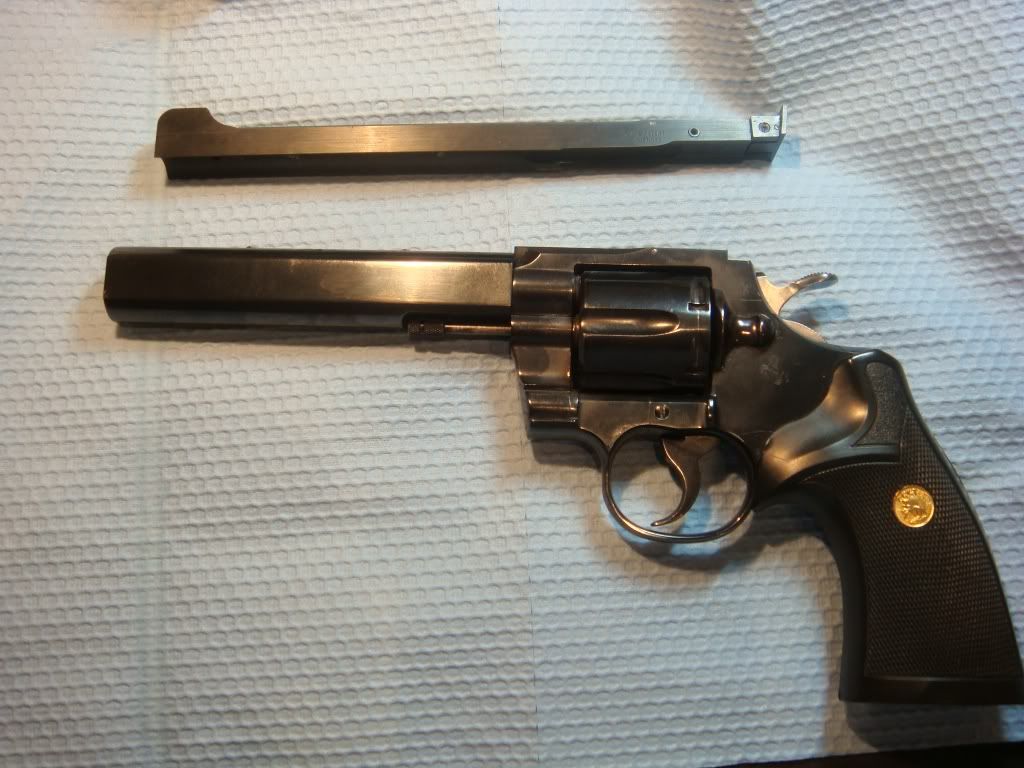

Recently had to sell a couple of colts, which is a good way to finally get some photos taken. Seems like filtered overcast light highlights blueing well.

Labels:

porn

photobucket must die

I cannot believe these slimy scumbags.

Their brilliant moneymaking scheme: if you upload more than some threshold of byte then --- rather than block further uploads for some amount of time --- they turn off *all* your photos unless you pay extortion money ("go pro!") to get them to release them.

Further, while paying, each time you click some option they will silently tick a "please set up recurrent billing!" box to try to parasite away more funds.

I cannot wait until this collection of inbred suits gets wiped off the planet.

Their brilliant moneymaking scheme: if you upload more than some threshold of byte then --- rather than block further uploads for some amount of time --- they turn off *all* your photos unless you pay extortion money ("go pro!") to get them to release them.

Further, while paying, each time you click some option they will silently tick a "please set up recurrent billing!" box to try to parasite away more funds.

I cannot wait until this collection of inbred suits gets wiped off the planet.

Labels:

not-blam

Monday, December 28, 2009

The french and boundary issues

Innocently reading an economics blog ("marginal revolution" http://www.marginalrevolution.com/marginalrevolution/2009/12/assorted-links-23.html) one clicks on the second link down and gets: http://www.

If you have a tough constitution and vile humor, watch the video. They use "audacious" and "stability" in ways that one would never imagine. Only $400EU!

Labels:

not-blam

Thursday, December 24, 2009

Good writeup: CA vs TX

Simple strategy: spend less, get more. http://www.city-journal.org/2009/19_4_california.html

Hat tip: MR.

Hat tip: MR.

Labels:

current events,

not-blam

Tuesday, December 22, 2009

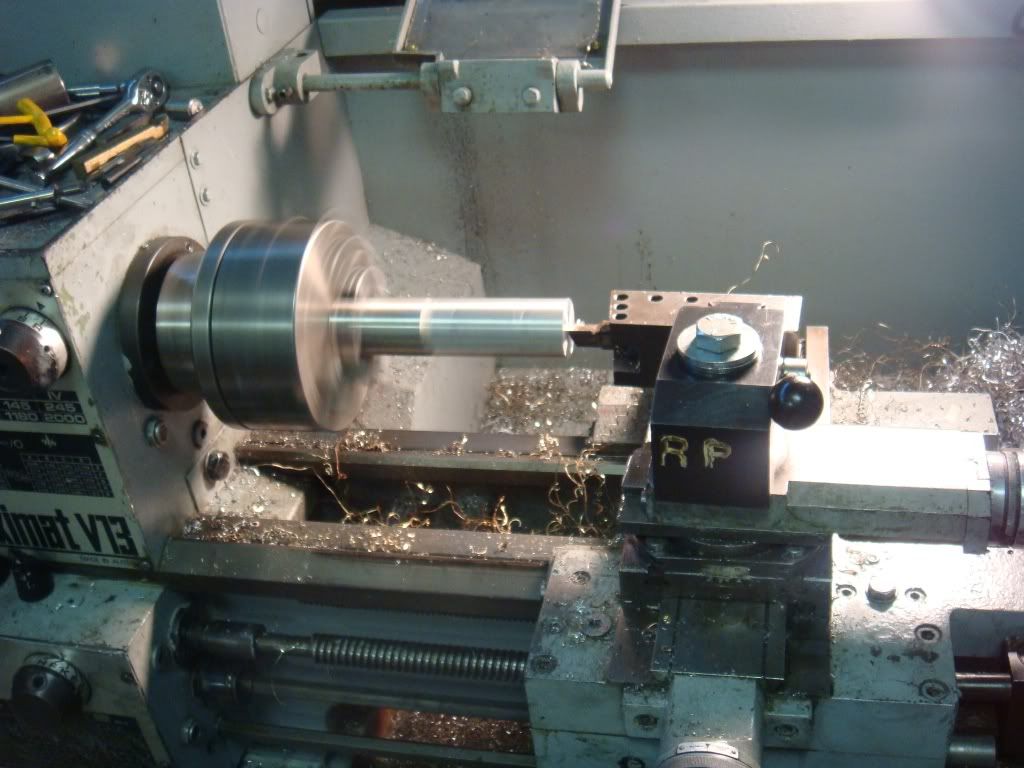

emco v13 cutting 1/2" toolsteel to nothing in one pass

Could go faster, easily. I really love this model, the thing eats SS like aluminum:

The best takedown of any movie, ever.

This can't possibly work, but does: Some amateur guy put together a 70 minutes long(!) destruction on "phantom menace" a movie I've never seen (and hope you never do either). It's really really good. Very concrete and self-contained so you need not ever (ever) get close to that which it hates on.

Labels:

not-blam

Wednesday, December 16, 2009

rhetoric over reality: brit scientist fired over looking into the relative lethality of different drugs

Article here: http://www.boston.com/bostonglobe/ideas/articles/2009/12/13/you_cant_handle_the_truth/

The adviser, Dr. David Nutt, said in a lecture that alcohol is more hazardous than many outlawed substances, and that the United Kingdom might be making a mistake in throwing marijuana smokers in jail. His comments were published in a press release in October, and the next day he was dismissed. The buzz over his sacking has yet to subside: Nutt has become the talk of pubs and Parliament, as well as the subject of tabloid headlines like: “Drug advisor on wacky baccy?”

But behind Nutt’s words lay something perhaps more surprising, and harder to grapple with. His comments weren’t the idle musings of a reality-insulated professor in a policy job. They were based on a list - a scientifically compiled ranking of drugs, assembled by specialists in chemistry, health, and enforcement, published in a prestigious medical journal two years earlier.

The list, printed as a chart with the unassuming title “Mean Harm Scores for 20 Substances,” ranked a set of common drugs, both legal and illegal, in order of their harmfulness - how addictive they were, how physically damaging, and how much they threatened society. Many drug specialists now consider it one of the most objective sources available on the actual harmfulness of different substances.

That ranking showed, with numbers, what Nutt was fired for saying out loud: Overall, alcohol is far worse than many illegal drugs. So is tobacco. Smoking pot is less harmful than drinking, and LSD is less damaging yet.

He was swiftly booted from his government position. Home Secretary Alan Johnson said Nutt had crossed a line. He “cannot be both a government adviser and a campaigner against government policy,” Johnson told The Guardian newspaper.

"It was a funny, kind of petulant reaction,” Nutt told the Globe, “all about machismo and politics. We’re harder on drugs than you, we’re tougher.”

Labels:

not-blam

Sunday, December 6, 2009

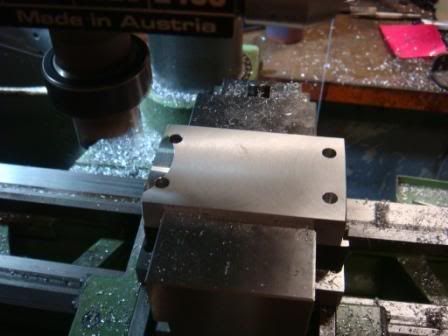

Fly cutters rock!

OK, I know I am about 100 years late to this particular party, but I have to say that fly cutters are freaking awesome! I'd always heard about them but just throught "WTF do I need another tool for?" Turns out that was pretty stupid.

The phrase you need to remember is "poor man's surface grinder."

Once you figure out how to grind the tool correctly you'll have fun. I've been squaring up aluminum for hours for no particular reason.

Pixels beat letters, so let's get to it.

I recently picked up an emcomat 8.4 mill/lathe combination. Generally I have a low opinion of combination machines (fish nor fowl) but Emco has a wonderful reputation for high Austrian quality and this machine lived up to it. It's a pretty sturdy machine (400lb?) for its size, and like the other emco's I've used cuts way above its weight. As a nice touch, the previous owner hand cut 10 quick change tool holders:

We have a rough piece of aluminum that we start making a cut on:

Labels:

machining

Fixing a 3-jaw emco chuck

So, among the many things wrong w/ an Emco V13 engine lathe I picked up (not it's fault), the chuck had been sorely abused and required serious cranking to turn the key towards the end. This is a short post on fixing it.

I'd not seen something written up (though I'm sure there has been, many times). And it's definitely not rocket science. However, sometimes it's useful to realize something is not rocket science so you actually do it. In this case fixing the problem made a big difference, though it still remains to a slight degree.

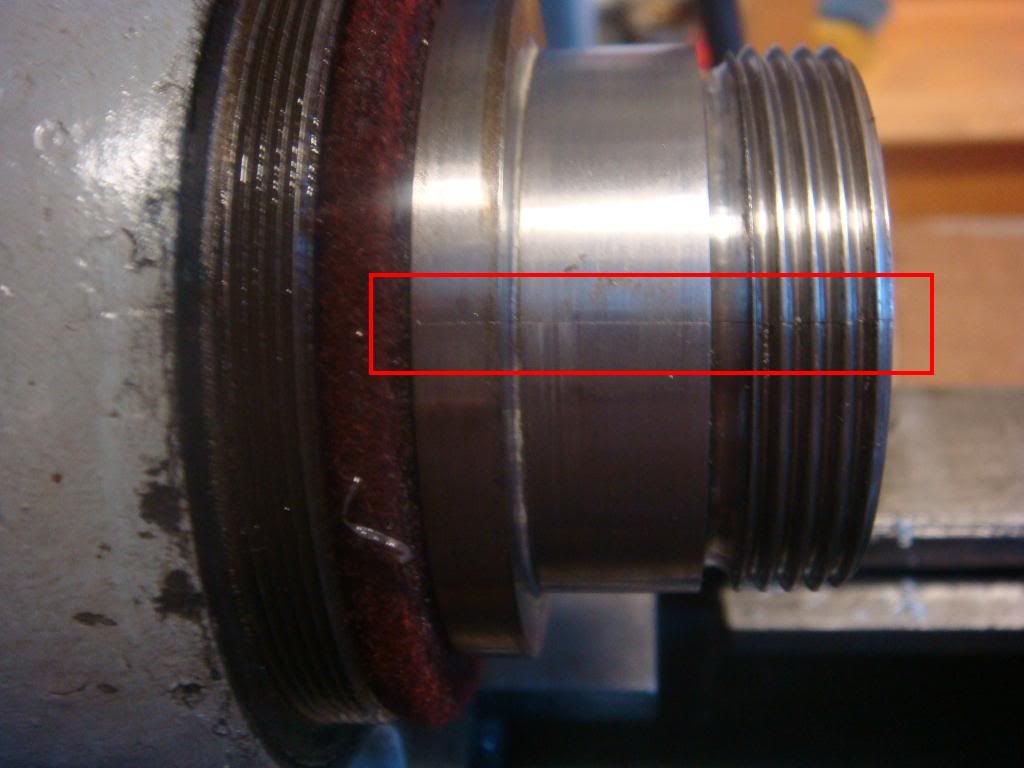

Here's the chuck. V13's have a D1-4 mount:

Adding a modern toolpost to a V13 Emco lathe

My Emco V13 lathe came with a four way toolpost. I'd rather do dishes than use shims, so that had to go. I have a 200 series KDK post with around 8 holders, so that'd be the obvious way to go. Unfortunately the press fit screw used to hold the post in the emco didn't fit the KDK --- too small at top, too large at bottom. I couldn't modify the KDK either --- it's hard enough that it ate some carbide endmills I tried to use to cut it and probably woke the neighborhood. And there's no dovetail on the emco.

So we need to make a new bushing to press fit into the compound rest. It was thanksgiving eve, so it was a perfect project. (I don't have a TV.)

Here's the emco's compound rest w/ the tool post screw sticking out:

Thursday, December 3, 2009

Awesome: TX style depositions rock

Accents, beat down threats, and tomfoolery. Must watch: http://www.youtube.com/watch?v=ZIxmrvbMeKc&feature=player_embedded

More fun at: http://www.businessinsider.com/deposition-videos-you-have-to-see-to-believe-2009-12

More fun at: http://www.businessinsider.com/deposition-videos-you-have-to-see-to-believe-2009-12

Labels:

not-blam

Wednesday, December 2, 2009

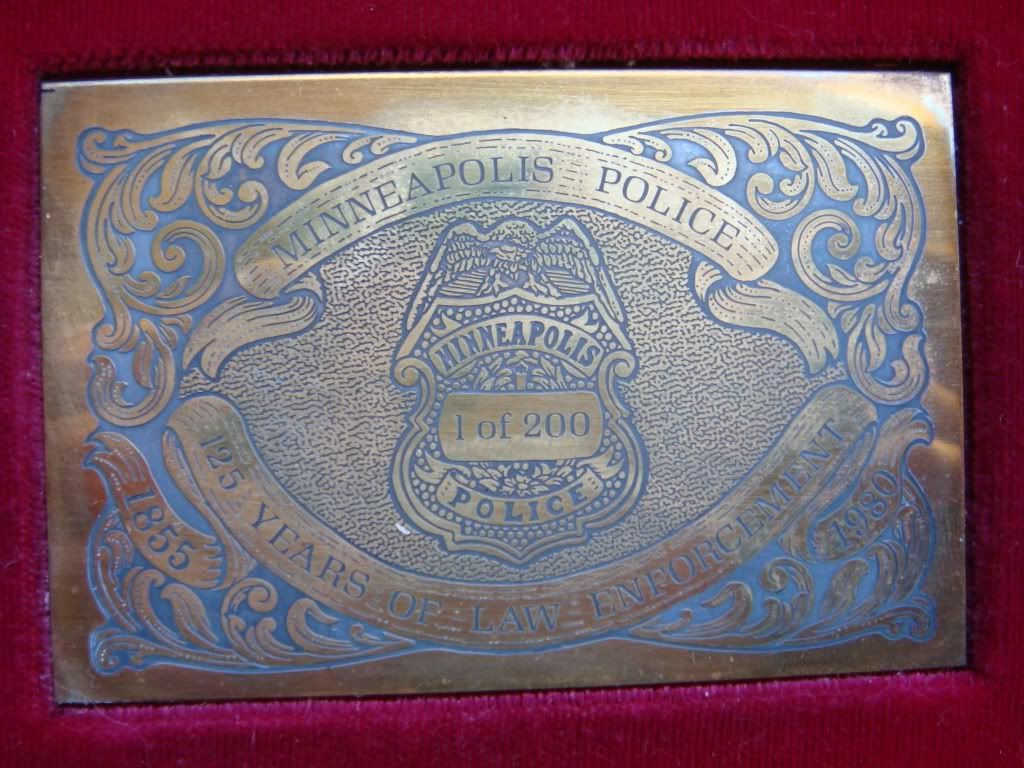

Memoria

I've been getting a bunch of old machines and revolvers. Since they are generally older than 50 years, all the original owners are dead. It's a strange feeling to be working late at night, where almost everything you touch belongs to a ghost.

Initials on tools seem more appropriate markers than text carved on stone:

Initials on tools seem more appropriate markers than text carved on stone:

Labels:

gunsmithing,

machining

Tuesday, December 1, 2009

Part II: retrofit of an Emco Compact 5 CNC lathe

This is a delayed follow up to the post on disassembling an Emco Compact 5 CNC (http://coltpython.blogspot.com/2009/10/part-i-retrofit-of-emco-compact-5-cnc.html) on putting the machine back together with new bearings, motors, etc. I did this a month or so ago; hopefully this doesn't leave out anything important.

Note: this writing is *way* too detailed for a real machinist. It includes a bunch of very basic steps since that's the level I'm at.

It's currently at around 80%: motors in, everything turns, but still have:

- hook up limit switches, the motor, the shutoff switch, and the RPM encoder to the gecko g540.

- do something about the cosmetics: I ripped out a bunch of the stock electronics, leaving empty holes. These will suck up dust and junk, so need to decide what to do.

- getting the optical encoder to not drag as the spindle turns. It turns out you have to bolt the lathe in and push/pull it back and forth so that the sheet metal of the housing torques until the drag stops. I kept disassembling the spindle head (and trying to seat the flywheel assembly deeper) in a misguided belief that these were the problems.

- You probably 't just bolt the motors right on and go --- you need to make sure the tension is sufficient. So push the motors away from the timing belt wheel until the belt is tight and then tighten the bolts.

Finally, I still cant' get mach 3 to run reliably on windows XP on a Thinkpad T61 laptop, but this seems to be a known problem.

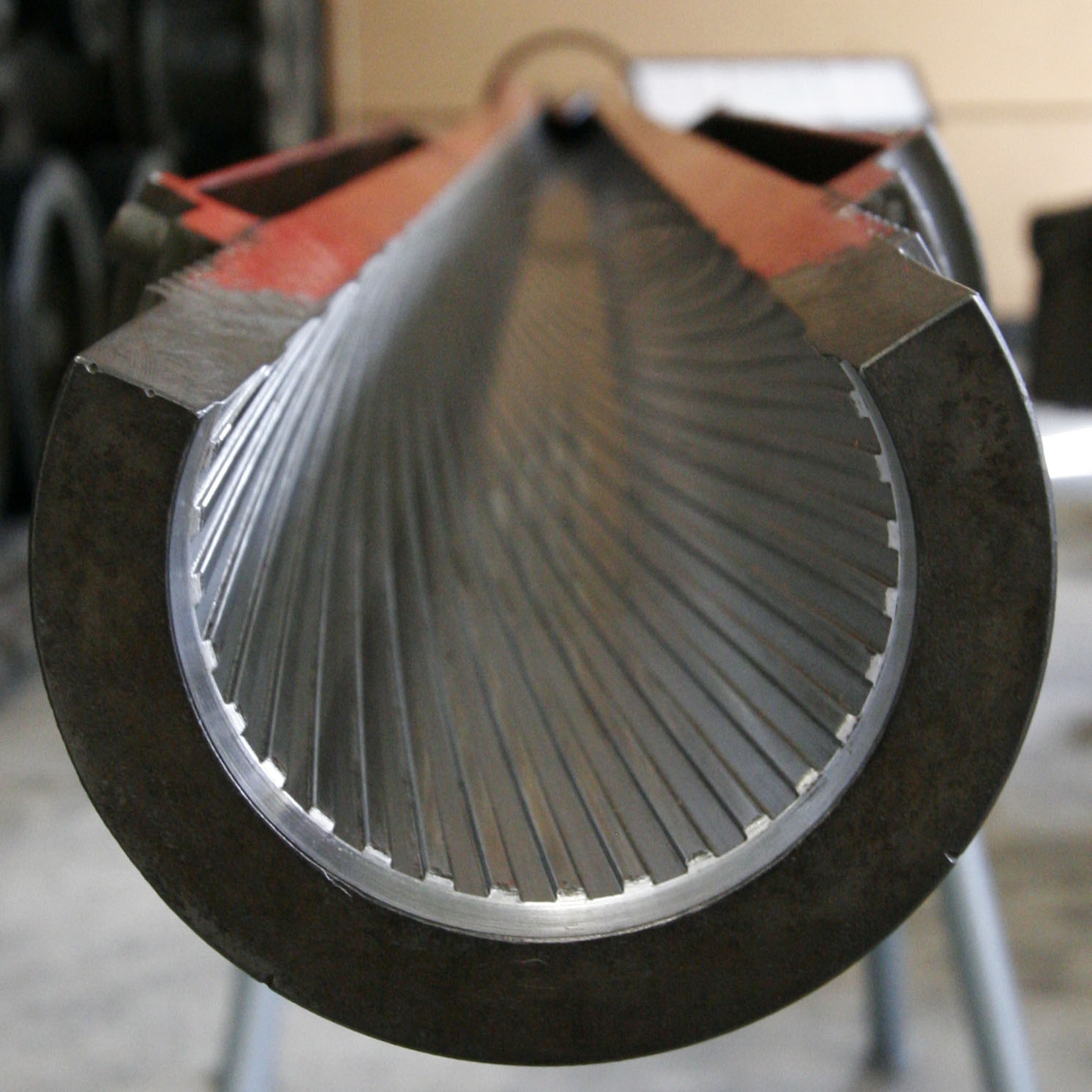

replacing timing belt on wells index CNC

Not exactly a universal problem, but: I have a wells index 700 series CNC mill that when you put into traverse mode gets stuck frequently. It seems to be a timing belt issue, esp since the belt broke when trying to adjust the motor. This is a short post on replacing the belt since I couldn't find any documentation.

As a bit of background, if the documentation is correct, it weighs more than 3,500lbs. Unfortunately, when it was moved, the servos got whacked and it's been a problem getting it running when controlled by computer (manual is fine).

The Y axis drive was giving a lot of problems for a while, until a real machinist came over, moved the motor around and then it worked. Turns out it had been hit and moved slightly out of alignmnet --- this was making it slightly more difficult to turn the handle, which was causing the torque sensor to stop movement.

I started getting the same problem on the X axis so started fooling around, and making it tighter. 20+ year old belts don't like to be made tighter and this one promptly broke.

I paniced.

I then called the company and the owner hadn't had to deal w/ that before (?!) so wasn't sure what to do. He said he'd get back to me. He then said I could maybe get the table to seperate and go from there. These instructions were fairly vague to someone that don't know much about machines.

In any case, it sucks having a broken machine so sans documentation I started taking bolts off. Turns out it was actually not that hard to replace the belt, despite some initial false starts.

Here's more photos than anyone other than the one wells index owner out there would want to see :)

Monday, November 30, 2009

Now why would we need people who know how to make stuff for money?

Good example of quantitative data making a tendency obvious in a way that concatenating a bunch of nouns and verbs together can't.

From: Nick Shultz, pointer from Bainbridge.

From: Nick Shultz, pointer from Bainbridge.

Labels:

current events

porn causes tsunamis & earthquakes

well, at least in Indonesia, depending on the govt' official:

http://scienceblogs.com/pharyngula/2009/11/porn_causes_tsunamis_and_earth.php

Hat tip: BT

http://scienceblogs.com/pharyngula/2009/11/porn_causes_tsunamis_and_earth.php

Hat tip: BT

Labels:

current events,

not-blam

Saturday, November 28, 2009

If you thought cars might have a bad effect on reality

just wait til an errant spaceship can destroy the solar system: http://www.newscientist.com/article/mg20427361.000-dark-power-grand-designs-for-interstellar-travel.html?full=true&print=true

Interesting discussion of how to harness artificial black holes to go really very fast.

Hat tip: Marginal Revolution

Interesting discussion of how to harness artificial black holes to go really very fast.

Hat tip: Marginal Revolution

Labels:

not-blam

Thursday, November 26, 2009

Amusing analysis of the climategate code

So, let us stipulate that it would be a big surprise if burning tons of oil and its progeny had no significant effect on reality. However, the basis of these warmist predictions are the numbers spit out by large programs written by climate guys. And, generally, scientists can't code worth a shit.

To make this specific, there is an interesting, truncated, walkthrough of a couple of files in the main simulation program at:

http://www.di2.nu/200911/23a.htm

More analysis here: http://wattsupwiththat.com/2009/11/25/climategate-hide-the-decline-codified/

If you like such things, there's inf similar things (in different domains) at: http://thedailywtf.com/

To make this specific, there is an interesting, truncated, walkthrough of a couple of files in the main simulation program at:

http://www.di2.nu/200911/23a.htm

More analysis here: http://wattsupwiththat.com/2009/11/25/climategate-hide-the-decline-codified/

If you like such things, there's inf similar things (in different domains) at: http://thedailywtf.com/

Labels:

not-blam

Wednesday, November 25, 2009

cool science tattoos

http://blogs.discovermagazine.com/loom/science-tattoo-emporium/

For example, everyone's favorite: Darwin Kong

For example, everyone's favorite: Darwin Kong

Labels:

not-blam

Sunday, November 22, 2009

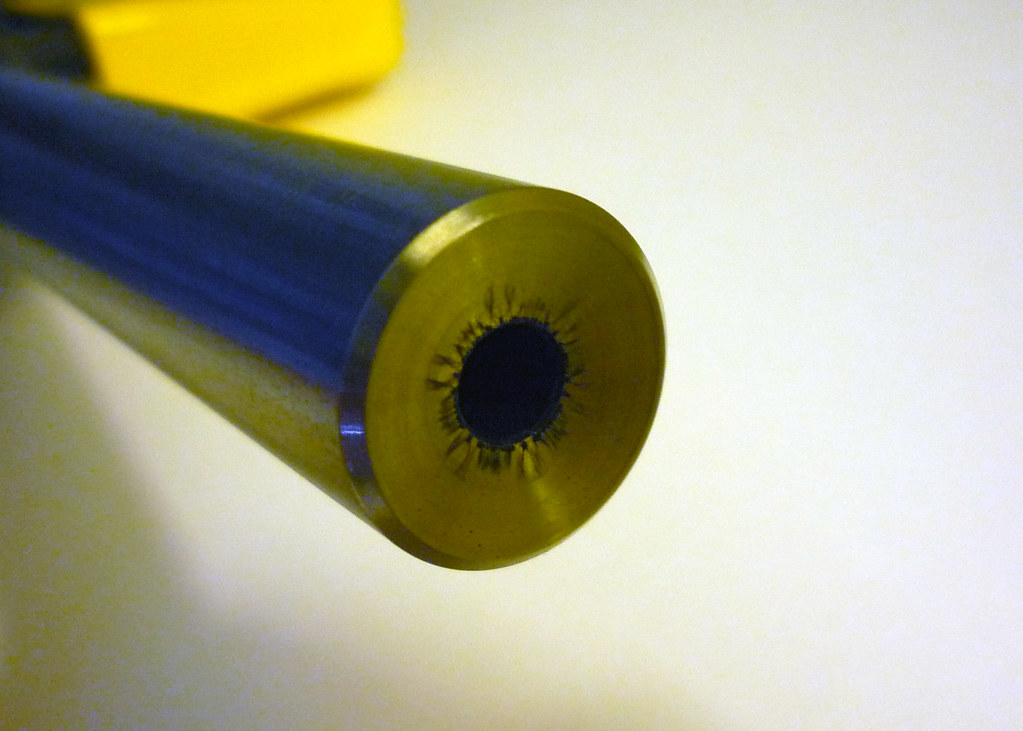

Relatively inexpensive reamers for rechambering

http://www.pacifictoolandgauge.com/products.htm

And a how-to on rechambering a 50cal: http://www.riflebarrels.com/articles/50calibre/chambering_50cal_rifle_barrels.htm

And a how-to on rechambering a 50cal: http://www.riflebarrels.com/articles/50calibre/chambering_50cal_rifle_barrels.htm

Labels:

gunsmithing

Friday, November 20, 2009

AVOID "Road Runner Transportation Services" they will destroy your shipment and not reimburse

Short version: I bought an Emco V13 lathe in august, it was transported by "Road Runner Transportation Services" who as part of the delivery ran a forklift into it, basically totaling it. They've dragged things out for months. Their latest offer is that they will pay me $140. Given that the lathe cost $2600 and shipping was around $700 this is disgusting.

There's no abiguity: they fucked up, destroyed a good quality piece of equipment and are too dishonest to do the right thing. I'm going to have to sue them to straighten this out, which is a big waste of time.

I'd recommend avoiding them at all cost.

Here's some photos of the damage when it was delivered.

Labels:

machining

Friday, November 13, 2009

Fixing my dad's 357 trooper

My dad bought out a Colt 357 trooper with some problems: these are I frames, identical to pythons on the inside. This is a short writeup on fixing the problems (for the most part). Note there's no sexy action work here, just a few fairly typical problems and one weird one. I write this stuff up so I don't forget, but no guarantees about riveting narratives.

The first problem: the cylinder does not spring back when you push it:

Labels:

gunsmithing

Thursday, November 12, 2009

Tuesday, November 10, 2009

forensic photos: 2.5 ported armoralloy python

It's been a while since I opened a python side plate, which at my age means I'm just about to forget everything. So, to counter that my dad and I went through a 2.5 ported python has that someone went through some trouble for to make into a very (very) nice carry gun with a great trigger and excellent porting.

Here's what we have to work with:

Labels:

forensics,

gunsmithing

Saturday, November 7, 2009

One of my favorite python sight combinations

This is a great setup. A Kensight "Elliason" rear (you can buy these at Brownells) with a front sight that was thinned a couple hundredths of an inch using a milling machine.

Front:

Rear:

Labels:

gunsmithing

Friday, November 6, 2009

Thursday, November 5, 2009

interesting article on the coming crisis in city bonds

http://blogs.law.harvard.edu/philg/2009/11/03/the-coming-collapse-of-the-municipal-bond-market/

High bit: no fucking way you should buy city bonds.

Amusing bit: with no way to default, West Palm Beach, Florida had to raise property taxes to 42.5% in order to meet obligations.

Possibly useful: in terms of debt vs GDB and citizens: "Massachusetts comes in at #1, with more than $10,000 of debt for each citizen and 20 percent of GDP. Each Texan owes about $1,000, by contrast, or 2 percent of GDP.

CA sucks more in various ways: http://www.latimes.com/news/opinion/la-oe-voegli1-2009nov01,0,825554.story

High bit: no fucking way you should buy city bonds.

Amusing bit: with no way to default, West Palm Beach, Florida had to raise property taxes to 42.5% in order to meet obligations.

Possibly useful: in terms of debt vs GDB and citizens: "Massachusetts comes in at #1, with more than $10,000 of debt for each citizen and 20 percent of GDP. Each Texan owes about $1,000, by contrast, or 2 percent of GDP.

CA sucks more in various ways: http://www.latimes.com/news/opinion/la-oe-voegli1-2009nov01,0,825554.story

Labels:

not-blam

Wednesday, November 4, 2009

Success! Fixed Hardinge QC lathe

I bought a Hardinge Cataract Quick Change lathe awhile back that purported to be in excellent condition but, in fact, was completely inoperable.

It's now been resurrected with some help from a Practical Machinist member and a lot of time over the weekend. I'll be posting photos of how to take apart and reassemble soon, but here's some quick evidence: she cuts!

One weird thing about the QC is that the even on "low" the powerfeed is really fast, but even so, the finish on this is a very nice matte gloss:

Labels:

machining

Saturday, October 31, 2009

Interesting china photos

http://www.chinahush.com/2009/10/21/amazing-pictures-pollution-in-china/

The chinese are serious about their pollution:

The chinese are serious about their pollution:

Labels:

not-blam

Wednesday, October 28, 2009

Part I: retrofit of an Emco Compact 5 CNC lathe

I recently got a somewhat beat up Emco Compact 5 CNC lathe. I spent a bit of time retrofitting it. (Note: "Emco" is Austrian lathe as opposed to "Enco," cheap Chinese) While the manual has a schematic, I didn't see much on taking it apart, which is a bit nerve wracking since Emco doesn't seem to make replacement parts. This is the first chunk of photos from what I did. No guarantees it will help, but perhaps you can at least see things to avoid.

So here's what we have to work with:

Pretty dirty, some rust spots.

The spindle moves if you manually program it, but there's no way to save programs other than a tape player(!) and no way to upload other than typing.

I bought a plug&play CNC setup from dmauch@seanet.com, which includes a set of Nema 23 500oz motors and a GeckoG540 controller. You can drive it using Mach3 or (hopefully EMC2).

In any case: first thing is to strip the lathe down.

Tuesday, October 27, 2009

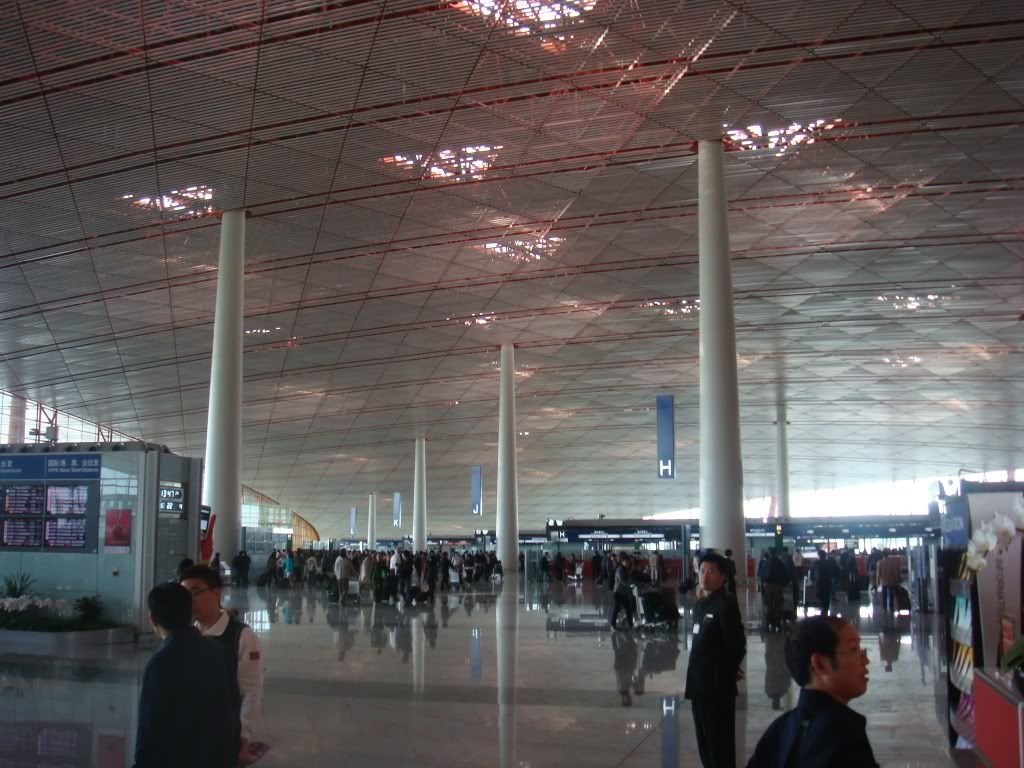

Recent trip: beijing, Oct 2009

Some things right off the bat: it doesn't look like your dad's china anymore. If you just looked at the buildings, you'd think it was some new place in EU or a new version of new york. If you looked at the people, you might think HK. Definitely not what I expected for china. At least from what I saw, it's much less crowded than NY (where you constantly feel as if you are drowning in meat) or even downtown SF. And the air was clean, which seems impossible, but there you have it.

And the people had their pluses and minuses. I'm still not used to nicely dressed females clearing their throats like truck drivers and casually spitting on the floor inside a building. And the matter of fact way that Beijing people lie is startling. If you ask a question that they are too lazy to find the answer too will cost them money it seems fairly standard to lie right to your face. One example: a guide was trying to get us to go see some tourist thing, but we told him we were going to the forbidden city --- "Oh, you can't do that, they close at 3pm!" Which, of course, was complete bullshit. And thing was, it was trivially easy to falsify this claim since the gate was just 10 yards away. Stupid. Another favorite: if you ask a question they don't want to answer they just look away. Example again: taxi drivers parked by the side of the road "Are you working now?" which triggers no response and a studious look to the side.

Right off the plane, you can see a trend:

The airport is huge, with lots of space, and clean:

Labels:

not-blam

Saturday, October 24, 2009

Tuesday, October 6, 2009

recent trip

I haven't been posting much about colts lately --- trying to learn electronics and build a couple computer controlled lathes.

But did have a chance to go on a trip. It was interesting. A lot of fire and the official ethos is: "don't f*cking complain and do something interesting."

Labels:

not-blam

Sunday, October 4, 2009

Useful hardinge repair links.

This is a nice writeup on how to replace hardinge spindle bearings: http://aafradio.org/garajmahal/Hardinge_spindle_bearing_replacement.htm

Disassembly/fix/reassembly: http://www.csparks.com/hardinge/

Labels:

machining

Thursday, October 1, 2009

Fixing malignantly stupid ubuntu linux and windows XP on a thinkpad

I've wasted two days trying to get any of my thinkpad laptops to drive some stepper motors. Both windows and linux have behaved like inbred meth heads when it comes to doing simple things they should handle.

Crashes.

Things now work.

Windows

I was having issues making the parallel port work. One suggestion was to change the "ACPI" option to "Standard PC" from it's current setting.

Easy enough. Seemed completely harmless since "Standard PC" seems less tricky than whatever was in there to begin with.

I did it.

Reboot.

Windows crashes.

Reboot

Crashes

Reboot in "Safe mode"

Crashes

Reboot in "last stable configuration"

Crashes.

Reboot in with recovery CD.

Can't recognize harddrive.

Mount the windows file system in linux. Copy a bunch of DLLs over to try to revert thing. Crashes.

Finally, the sysadmin here changed the "Serial ATA" setting in the BIOS to be "Compatability" rather than ATA.

Now the recovery CD could recognize the drive.

Reinstall. Freezes since I need a product key and the one on my laptop doesn't work.

Track down what it wants (what an insult given that it fucked up!)

Continue.

Things now work.

Linux

Linux is not necessarily any better.

Since windows blew up I installed the ubuntu linux distribution to try out EMC2 (a CNC program). The installation went fine.

Reboot.

Boot loader cannot recognize the harddriver! WTF! (Grub: error 18)

I spent around 4 hours trying to get something to work. Even trying to do a complete reinstall of windows using a rescue CD failed w/ errors that it couldn't find the harddrive.

Fixing ubuntu's complete stupidity turns out to not take many key strokes in the end:

- You need to get into the "BIOS" to change a setting: reboot your laptop

- Hold down one of the function keys (F1 works for me)

- It will take you to a configuration screen

- Select "security"

- Set the "hide disk area" option to "disabled"

- Reboot.

- Should work.

Labels:

cnc

Wednesday, September 23, 2009

neat machining videos

Start of ongoing list.

CNC porn:

- Hard core mass production CNC: http://www.youtube.com/watch?v=MwgobIVj4fU

- Another fun one by the same people: http://www.youtube.com/watch?v=lcGHtI9Lql4&NR=1

- And another for a mill: http://www.youtube.com/watch?v=3SUQKGu7F5w&feature=channel

- Fast CNC cutting: http://www.youtube.com/watch?v=sYqN90gHOZM

- Now this is a production setup: http://www.youtube.com/watch?v=-J4RlAmBuEo&feature=PlayList&p=199985F23F191210&index=1

- nakamura CNC lathe: http://www.youtube.com/watch?v=a3Gtr4WbtNw

- Indicating workpiece in seconds: http://www.youtube.com/watch?v=tn7A9PqNftY

- Steady rest facing: http://www.youtube.com/watch?v=ThVprkb2w6g

- Using CNC mill as lathe: http://www.youtube.com/watch?v=Ezx_hCSJDLQ&feature=PlayList&p=C228FBAE81E4F35A&playnext=1&playnext_from=PL&index=4

- Neat home brew CNC lathe w/ a crazy tool changer: http://www.youtube.com/watch?v=Y1IDHIcyHLY&feature=related

- Cheap to build CNC dremel mill (from instructables). Not powerful or accurate, but seems like a good starter project before building something serious: http://www.youtube.com/watch?v=6drMZqmyXQc

- Same guy: building cheap CNC driver board: http://www.youtube.com/watch?v=ZUyqscxLJ4k&feature=related

Tuesday, September 22, 2009

For those poor suckers living in CA: call Schwarzenegger *NOW*

AB962 is sitting on his desk. It will ban mail order ammunition, along with other problems. If he does not actively veto it by Oct 11 it becomes law.

What to do:

Step 1: call 916-445-2841 Step 2: Press 1 for English. Step 3: Press 2 for commenting on a bill on the Governor’s desk Step 4: Press 2 for AB962 Step 5: Press 2 for Oppose Step 6: Repeat as necessary (preferably once or twice a day). |

This is a malignantly spiteful bill that is useless for reducing crime. It will likely increase death/accident/injury given that it makes ammunition more expensive: the majority (in my opinion) of gun owners are already undertrained, and this will make it worse.

Labels:

not-blam

Monday, September 21, 2009

Stepper links

Since the main point of all this electronic stuff is to build some custom CNC machines, time to start a collection of links:

- Nice H-bridge tutorial: http://www.mcmanis.com/chuck/robotics/tutorial/h-bridge/bjt-circuit.html

- Some notes on doing motors on arduinos: http://www.ladyada.net/make/mshield/use.html

- Arduino on steppers: http://www.arduino.cc/en/Tutorial/StepperBipolar

- Good stepper tutorials: http://www.societyofrobots.com/member_tutorials/node/168 and http://www.societyofrobots.com/member_tutorials/node/120

- Reverse engineering which stepper wires to use: http://wwwhomes.doc.ic.ac.uk/~ih/doc/stepper/others/

- Even more stepper motors w/ lots of data:http://www.st.com/stonline/products/literature/an/1679.pdf

- Related: how to use an oscilloscope: http://www.doctronics.co.uk/scope.htm

Sunday, September 20, 2009

Fixing arduino upload problem on linux

Symptom: the arduino IDE will upload your sketch no problem, but using avrdude raw only works the first time. Pulling the USB cable out and plugging back allows it to upload again (once).

Solution: (from http://www.arduino.cc/cgi-bin/yabb2/YaBB.pl?num=1201441300): it seems to be a problem w/ the linux driver. Just insert "stty -F $(PORT) hupcl" right before the avrdude command (where PORT = the usb device such as "/dev/ttyUSB0"). E.g. in the Makefil:

It's such a relief to not have to use their IDE! Point+click to edit was driving me nuts.

Solution: (from http://www.arduino.cc/cgi-bin/yabb2/YaBB.pl?num=1201441300): it seems to be a problem w/ the linux driver. Just insert "stty -F $(PORT) hupcl" right before the avrdude command (where PORT = the usb device such as "/dev/ttyUSB0"). E.g. in the Makefil:

You may also have to set your baud rate to 57600 (at least for the 328p).

stty -F $(PORT) hupcl

$(AVRDUDE) $(AVRDUDE_FLAGS) $(AVRDUDE_WRITE_FLASH)

It's such a relief to not have to use their IDE! Point+click to edit was driving me nuts.

Labels:

arduino,

electronics

Thursday, September 17, 2009

Arduino. Or: How to hack electronics w/o knowing a damn thing

I've paused on the colt stuff to learn some electronics + micro-controllers (the little chips that get stuck in your car, fridge, cell phone, etc) so that I can build my own computer controlled machines. The "Arduino" boards are a great way to go about it. You can download code onto them from your computer across the USB port and then use this code to control electronic things you wire together and plug into the board. (E.g., by reading whether pins have power or not, and setting power out on other pins.)

The "hello world" program is to hook up a LED light + a resister to the chip and make it blink by turning a pin off and on. I've only ever used computers to toss around 0s and 1s, so it's neat to make them control atoms (sort of). Hopefully by the end of the weekend I can use it to drive some stepper motors that I can then attach to a lathe to make it computer controlled.

Here's a set of great class notes aimed at artists from "todbot" (http://todbot.com/blog/spookyarduino/ )

If microcontrollers and electronics has always been mysterious, I'd really recommend checking the notes out --- the audience is non-technical artists, so it requires minimal knowledge. On the other hand, it's not pablum. He shows how to build cool stuff quick.

If you are going to go this route, just buy the $89 kit at: http://oomlout.com/ards.html Everything included to go from nothing to cool things. A bunch of different projects, many variations. I've spent all friday night tweaking on it!

Useful links:

Useful links:

- A bunch of neat arduino links: http://www.tigoe.net/pcomp/code/

- Useful blog tutorial on how to use a voltmeter: http://www.ladyada.net/learn/multimeter/voltage.html

- And more generally an arduino tutorial at the same blog: http://www.ladyada.net/learn/arduino/index.html (Which turns out to be the person I bought my arduino chips from! She has a post on how to build a cell phone jammer: http://www.ladyada.net/make/wavebubble/)

- Soldering guide: http://www.epemag.wimborne.co.uk/solderfaq.htm

- The comments of this thread are very useful: http://todbot.com/blog/2006/12/06/arduino-serial-c-code-to-talk-to-arduino/

- Nice set of tutorials on arduino and many other related things: http://itp.nyu.edu/physcomp/Tutorials/Tutorials

- And, of course, the "official" arduino forums: http://www.arduino.cc/cgi-bin/yabb2/YaBB.pl

- Heat sink discussion: http://www.thebox.myzen.co.uk/Tutorial/Power.html

- Awesome electronics lessons: http://mysite.du.edu/~etuttle/electron/elecindx.htm

Labels:

arduino,

electronics

Tuesday, September 15, 2009

sending gcode to a bandit controller on a wells index CNC milling machine

There's at most one other person on the planet that needs this information, but since I spent hours (and hours (hours (...))) looking for it, here it is.

Currently I only know how to send using "hyperterminal" on windows. When it starts tell it to connect to the serial port (If you don't know what this is: you pull down the hyperterminal menu which will say something like com3, com4 or other --- just try these until it works).

You set:

To send a program to the bandit:

After it loads

I am using a laptop. Since modern laptops no longer ship with serial ports (at least mine doesn't) I'm using a USB-to-Serial converter from Frys. The first one I bought was broken, which really jacked up the whole process.

If anyone can figure out how to send using linux that would be great! I've tried cu, minicom, and a random com.c program from the net. Something doesn't seem right. The bandit red light of death goes on (so it received something) but it's definitely not the right thing.

Currently I only know how to send using "hyperterminal" on windows. When it starts tell it to connect to the serial port (If you don't know what this is: you pull down the hyperterminal menu which will say something like com3, com4 or other --- just try these until it works).

You set:

- data bits: 7

- parity: even

- stop bits 1

- flow control: hardware

- windows keys

- autodetect

- send line ends

- wrap lines

To send a program to the bandit:

- put in ext mode

- press "CE" and then "start"

- In hyperterminal "send ascii file."

N001&0The "N001&0" seem required at the beginning. And "M2" states its at the end of the program.

X-1.0

M2

After it loads

- put the bandit in run "continuous mode"

- hit reset (to put the machine to the beginning of the program)

- hit start.

I am using a laptop. Since modern laptops no longer ship with serial ports (at least mine doesn't) I'm using a USB-to-Serial converter from Frys. The first one I bought was broken, which really jacked up the whole process.

If anyone can figure out how to send using linux that would be great! I've tried cu, minicom, and a random com.c program from the net. Something doesn't seem right. The bandit red light of death goes on (so it received something) but it's definitely not the right thing.

Useful post on converting an emco compact 5 to modern hardware

I've been spending a lot of time trying to figure out how to build my own CNC.

This is a nice rundown on how to convert an emco compact 5 lathe by Art Fenerty (he wrote Mach 3):

And his continuation of the same post:

This is a nice rundown on how to convert an emco compact 5 lathe by Art Fenerty (he wrote Mach 3):

Just to kick in on costing of such a project ( having converted my emco PC5 last year. This isnt a plug for my software, I retired over a year ago from Artsoft, just info for those interested in such a conversion. )

My costs were..

Motor drivers, about 100.00 each ( 2 required. ), I used some I had from ebay that I got for about 50.00 each, prices vary, but I used 10uStep controllers @ 3amps, 24 volt. Gecko's work great, as will almost any microstep driver.)

Motors ( you can use the ones currently on a pc5, but they are very weak, or mine were anyway. You couldnt even feel the torque detents as you rotated them without power. 500oz inch ( approx) cost me about 50.00 each , but you dont really need that power. ( though its nice to have ). My power more than tripled on the axis, they cannot be stopped by hand at this point, and they are much faster.

Power supply ( the one in the emco can be used, no need for an additional one. You can tap the original power supply for 24 volts for motor drives, and the 110volts for the breakout board power. )

I also added a breakout board for interfacing. The breakout board from pmdx.com fits well in the spot where the original

emco pc com board fits in the machine. Cost approx $129.00 US. The mach3 web based form has photos of the conversion I did,

everythign fits well int he Emco casing and made my pc5 a much more usefull machine.

I also added a sensor for threading, and put a bolt in one of the original slots to trigger the sensor for speed and threading. Mouser electronics 653-ee-sb5v is the sensor I used. About $20.00 for that.

Of course I didnt have to pay for the software. :-)

The emco works very well now, has no file length limitations, and lazyturn generates code that runs pretty well if you have nothing else available. ( free from the mach3 web forum till I end up adding a final finish pass. ). The only possible dodgy part is the

threading. While threading short threads works well, after a couple inches of thread there is a bit of wander that makes the thread imperfect, though nuts do spin on with no binding. This is the result of single pulse per rev threading. Still being worked on slowly, but seems to work well for most threaders, depends on the pc and sensor configuration and setting as to how well it works.

So my total cost was about 350.00US or so ( somewhere about 175 EU ) , adding software would make it about 300EU for a complete conversion.

The same conversion would allow EMC or other software to run the lathe. If one used an encoder for the spindle EMC woudl do perfect threading on it, or if one can figure out the original sensor in the pc5 to feed the software. ( I never could get mine working but it may have been defective from the start, I never used it prior to converting, so I just tore it out and replaced it with my 20.00 sensor..)

Alternately, instead of a breakout baord a smoothstepper device, USB based could be used, the smoothstepper is also known for perfect threads. All I can tell you for sure is the upgrade makes the lathe run much better than stock, much more powerfull, faster, and more reliable. Much depends on what you use it for of course.

Thanks,

Art

And his continuation of the same post:

>>I searched around: is this the thread you mean on your conversion?

http://www.machsupport.com/forum/index.php/topic,214.0.html

Yup, thats the thread.

Wiring isnt as bad as it looks. Where you see I added a pmdx breakout board, is where the emco put their pc interface card. You just rip that out entirely. ( if you have the same machine I do.. ). Your new motor drivers wire directly to the pmdx board, so between the docs for the drivers and the docs for the pmdx, all the wiring is described. Now I added 2 drivers and a pmdx, and 2 motors, the motors wire directly to the drivers ( real easy to wire the motors.. ) , and the pmdx board simply gets a printer port cable which I wired to the pc printer port plug on the back of my emco.. and then it wires to the drivers.. ( step/direction and com ) so 3 wires to each driver from the breakout board. I put 2 7 amp drivers and a PMDX in the same area.. they all went in just fine and with little effort. Chinese drivers or geckos all run about 120.00 I think for pretty high current drivers.

As to the power supply, yell if you like when you get there, its easy to find the 24volt spot on the emco supply. Lots of current available so no extra supply is necessary at least on the PC5 version of the Emco, those two points on the emco ( 24vdc and common) wire to each of the drivers to supply power to them, the pmdx just gets a tap to the 120vac line inside. Again, pretty easy.

Thats it, no other wires really need to be done unless you want threading.. the sensor can be a bit of a bitch to wire if you dont do electronics, but again, yell when you get there, its only 3 wires to the sensor from the breakout board.. and then I put a screw in one of the slots of the slotted wheel, the sensor see's it on every spin. The sensor bolts in the same bolt holes the old emco sensor did as I recall. I can take better pics if you get to that stage. But you can cut fine without the threading sensor. ( I dont cut threads usually..). If your firend can get that sensor that comes with the Emco running, then even better as I do have a special plugin that will use an index slot and multislot timing pulses for threading. Tests show it works well, but there is a wandering after an inch or two. Still holds nuts fine, but with Mach3 dont expect Boeing quality threads unless you use a smoothstepper.. its simply a limitation

of running from Windows. On the bright side, for those that need perfect threads, this described upgrade isnt just to make the emco Mach3 compatible, its also EMC compatable at that point, so if you like linux, you can run EMC as well. ) or pretty much any other step/direction controller. Steve Stallings, the pmdx inventor is an EMC group member and pretty knowledgeable about such things, Im sure many could help you get that up and running.

By the way, the new motors simply bolted in the same spots the old ones did, no work required at all.. you just wire the 4 wires from the motors to the drivers.. pretty easy.. Any basic electronics person will find it painless to do such a job.. ( and many people who know only about basic dc wiring..). Ill post Mach3 settings for the emco if anyone wants them.. it configures pretty easy and runs real well. No limit on file size at all.

Just my opinion, but if one is to upgrade an emco, Id really recommend going this route simply because it makes it compatable

with pretty much any controller that will send step/direction commands. The future will probably bring about things like SCurve controllers, ( which smooth out motion quite nicely), or other advances in technology which , if you go proprietary you wont be able to take advantage of. We all know how long these lathes last.. pretty much forever, so having a standard type of control has its advantages. ( Emco's also seem to sell for more if they are step/dir controlled thus allowing a new owner to pick their favorite software. ). Price wise, it seems if anything quite a bit cheaper to go this route, and then its done and standard, but thats just my opinion.

I usually dont kick in on such discussions as some may feel Im pushing for Mach3 to be used, and since I wrote it Im obviously biased,but I am retired.. I only work on things like future control code these days. So that having been said, you should probably ask as many groups as you can what your best plan would be. Ive never used WelTurn , the specs dont appear to be shown real well so I cant tell you max speed vs EMC or Mach3. At about 900.00US it seems pricey to me,specially if you have to then add new motors, complete conversion to step/direction is about 300.00 to 400.00US if you stick with your emco motors, I just found my emco motors so slow they drove me nuts. Max speed on my machine is set for 554 mm/minute, I could go quite a bit faster, but at 554 I never lose steps unless I jam into material. ( In fact the carriage would snap my hand off if I tried to stop it..), acceleration is set to 91mm/sec^2 and standard setting is 2000steps/mm. ( because I have it set to a high uStep setting, which is nice if your drivers support that. ). I tend to limit my speeds because using max speed rates on something like an Emco does stress it too much, but 550mm/sec seems very doable, and my lathe has no trouble with it at all.

At 2000steps/mm, Mach3's lowest kernal speed of 25Khz can do 720mm/min max, higher kernal speeds could double that quite easily if your motors can handle it, but I dont suspect an Emco can handle a meter a minute. My motors were advertised on Ebay for 750oz in, (Deep Groove) but I dont really believe it, I thing they are 500oz in or less, but I have to admit they are very powerfull, orders of magnitude above the steppers that came with my emco, the difference is not only audible, but amazing and very powerfull, the original motors I could easily stop with one hand, I would'nt recommend anyone trying to stop these puppies with their hands..not if they like having hands. :-)

My only problem is that my lathe has the AC motor driven spindle , which makes it quite low torque, my buddies emco ( You can see Brians on the group forum somewhere as well ) has the DC motor spindle, and Ive seen him do 1/4" of steel in one pass ,

(in fact theres a video somewhere showing it do that at a pretty high feedrate. Perhaps emco's with dc spindle can all do that, I only know the few Ive worked on). To me thats a pretty high rate of speed for 1/4" in one pass. No possible way my spindle could do that, I limit to 1mm per pass or less usually, but since feedrate is quite fast it doesnt seem an issue to me. I cant see any posting of welturn max speeds or step rates on their site, perhaps someone can post their experience in terms of speed and at which point they start to lose steps. Any comparison would be interesting to those considering updating hardware or software.

The welturn software does seem very nice to use from what I can see though, and any software is an upgrade from the original dos version of emco IMO , it seems pretty limiting and pretty non-standard in its Gcodes. CNC is all about standards what with the CAM packages available. Each person has their own requirments though, so check out every option as thoroughly as you can before you make a decision.

Again, this is all just my opinion, I know of many emco's that run Mach3, and several that run EMC, all seem pretty happy. Its not

a conversion project that should scare anyone with $400.00 or so to burn.. took about 3 hours to do mine, of course it may take

longer if your not used to cnc wiring, but its not brain science and very little wiring really needs to be done. Threading seems the only real issue, there are several ways to do it, and performance there will vary with software, methodology, sensor and experience.

While I think of it, the other issue you may want to think about is an auto tool turret if you have one, ( I dont ), Mach, and EMC can be configured for it, the pmdx interface board has lots of spare outputs when used with a lathe, and macro's can be written to

run it, but I havent done any for myself. From what Ive heard when I did support they just used a timed macro to run the motor, wait for a switch to hit, then run backwards for a couple seconds to jam it into position. You can also do things like add lights, blinking indicators that job is complete, relays for various optional functions.. all advanced topics if you do go that route... the various support groups are pretty good with information on such things.

Hope these thoughts help, sorry for the verbosity.

Thanks,

Art

Wednesday, September 9, 2009

a useful healthcare comment

Usually blog comments are worthless (or worse). This one is a welcome counter point to the typical nattering:

Full text at: http://meganmcardle.theatlantic.com/archives/2009/09/political_theory.php#comments

Thorley Winston:

My preference for health care financing reform (since no one is really not talking about health care reform) starts with:

a) Give consumers who buy health insurance the same tax breaks as employers who buy health insurance for their employees (no fines or mandates) or make all health care costs fully tax-deductible. I’m not a fan of employer-based health insurance but most people are satisfied with but I think we can at least give those in the personal health insurance market the same tax treatment.

b) Allow consumers and employers to buy health insurance policies across State lines like we can for life insurance, auto insurance, and every other legal good and service (if you want competition, that’s the way to do it).

c) Remove barriers to allow small businesses and other organizations to form Association Health Plans (about 60% of uninsured Americans work for small businesses).

d) Encourage high-deductible policies that cover catastrophic illnesses and Health Savings Accounts. These policies tend to have lower premiums (which make them more affordable especially for younger and lower income people) and we can start to develop a more robust market (along with price signals) for routine care costs instead of having them covered by third-party payers.

e) Automatically enroll those who are eligible for Medicaid in Medicaid (about 25% of uninsured Americans are those who are eligible for Medicaid but don’t enroll until they need to see a doctor).

f) For the poor who don’t qualify for existing programs and/or for people with preexisting conditions for whom it is still cost-prohibitive to buy health insurance, let the States experiment with targeted subsidies or creating insurance pools for these individuals.

g) Give doctors who provide unreimbursed care a tax deduction or tax credit for charity care.

I haven’t addressed several issues like medical malpractice reform and Medicare reform (both of which I think we desperately need in our country) because I think they’re volatile enough that they need to be addressed separately. I also think we need to (on the health care side of things) look FDA reform for drug and device approval, increasing the number of doctors in the country and/or the ability of other trained medical personnel like nurses and physicians assistances to provide services, health IT reform, wellness clinics, etc. All of these are important and distinct enough that I think they can and should be addressed separately instead of being thrown into a thousand plus page bill that sinks under its own weight.

Full text at: http://meganmcardle.theatlantic.com/archives/2009/09/political_theory.php#comments

Labels:

not-blam

Monday, September 7, 2009

Before killing doctors, let's do lawyers first.

Funny op ed in WSJ on doctors regulating lawyers. That would be, literally, "change you can believe in":

http://online.wsj.com/article/SB10001424052970204731804574387021307651050.html

Hat tip: volokh.

http://online.wsj.com/article/SB10001424052970204731804574387021307651050.html

Hat tip: volokh.

Labels:

not-blam

Sunday, August 30, 2009

Diagnose that colt #2!

I was going over a m357 I'd tuned for my dad, correcting some issues. I replaced the rear sight with one of the very nice kensights (clone of the elliason) available from brownells and, since the sight was off, just to be thorough I went to take off the firing pin plate to clean out the recess.

As my dad watched, I had an incredibly hard time getting the firing pin plate off. And then it was just about impossible to get it back on.

This, of course, should never happen. A child with a punch can get the plate off and on --- there's really nothing tricky, nothing to go wrong. If you see anyone having a hard time with it, they really must not know what they are doing.

When I took the pin and spring out the plate would go in w/o any issue.

Any guesses for what the deal was? It was kind of amusing. Kuhnhausen has a warning about such things, but I always skip it thinking "irrelevant information."

One of the other issues was that when reblueing, the person couldn't be bothered to take the bolt off, and essentially sheared the end down to a flat with the buffer. This seemed to cause it to come loose under fire.

So, after having all the difficulty, it eventually dawned on me that the only real reason it could be hard to get in w/ the firing pin in place but not without it removed was that the spring must not be compressing enough. Well how could that be? Oh, did they ... ? Yes they did!

Answer below after a few line feeds :)

Here's a stock firing pin spring and bolt screw on the left, and the spring we have in place and the sheared bolt screw on the right:

Labels:

gunsmithing

(Sort of) making a longer python firing pin

I've seen various references to longer firing pins, titanium firing pins, and otherwise weirdo modifications. It always seemed pretty exotic and not something you'd ever run into in real life, but it turns out that making such things is actually fairly simple.

I just got an Emco (not Enco! It's Austrian, not Chinese) Compact 5 bench lathe on ebay, so this seemed like a good project to try.

It's right before bed, so results were "OK", but presumably with a bit more focus they will turn out the way they should.

One great result is that the compact 5 is a fantastic lathe. It must weigh less than 80 lbs, but despite not being anchored to anything (yet) and not being leveled (yet) or any of the things a reasonable adult would do, if I cranked the RPMs high and used carbide it would cut the metal I have like butter even on fairly heavy cuts. This thing is awesome. I think I can actually bore out cylinders on it; it's certainly possible to make the bushings that fix endshake.

Here's the lathe, with the steel rod, a carbide cutter, a poor man's digital readout (which I took off) and an A2Z quick change tool holder which I have mixed feelings about:

Thursday, August 13, 2009

Forensic photos: Cylinder and Slide python

I bought a CR-B ($312) and CR-C ($466) package from C&S so I could see how they work on things. The CR-C is their premier colt package; I got it done for an SS python. This post is to dissect the work they did. As they describe it:

CR-C - Colt Revolver - Package CR-C

Colt Python, Diamondback, Detective Special, SF-VII, DS-II Revolver Super Tune Up. Customer Must Specify Whether this Weapon is for Duty/Carry or Target Use Only.

Super Action Job on Python, Diamondback, Detective Special, SF-VI or DS-II

Chamfer Cylinder Mouths and Polish Chamber - 38/357 and 44

The following items will be checked and corrected as necessary: Crane and ejector rod straightness, barrel to cylinder chamber alignment, barrel turned up square with frame, barrel forcing cone square, re-cut forcing cone as needed, barrel muzzle crown

Test Fire for Function and Adjust Sights for Zero at 15 Yds.

Return Shipping and Insurance - Will be Arranged with Customer at Time of Shipment.

They did a couple of very interesting things I hadn't seen before. And they did one very surprising thing I had seen before but didn't realize was still being used (hint: "Austin Behlert" action job).

Unfortunately, despite the novelty, the end result --- how the DA actually feels --- was not worth the money. The SS python feels better than stock, but no where near as good as the colts I have that were done by Frank Glenn or Reeves Jungkind (or even me!). It sounds like there has been a change in personal, since other people have had excellent results w/ C&S previously.

As on additional warning, they corrected the barrel cylinder gap on both guns, but did not clear it with me first. The total bill was over $1200!

In any case, let's get to it.

Here's the SS with it's clothes on:

Labels:

forensics,

gunsmithing

Tuesday, August 11, 2009

Another vote for outers (or a DIY equivalant)

This has been gone over numerous times, but in the spirit of repetition, here's another vote for outers (or an equivalent) foul out electronic bore

For those of you that are industrious and don't want to pay $109 or so, here's what seem to be a reasonable set of instructions for how to make your own (flashlight not included):

http://www.surplusrifle.com/reviews/copperout/index.asp

I started w/ two colts that I cleaned completely. I used a brass brush with lead out and hoppes, then patches, etc. I then degreased them and ran them through Foul Out. Out came a bunch of black gunk, despite the many passes w/ the brass brush. This has happened pretty much each time I've used it. Seems worth doing, sometimes. It's kind of a hassle, but life is tough.

Here's a 2.5 python strapped in with outer's rod inserted + solution:

Monday, August 10, 2009

Diagnose that colt #1!

A pretty common question goes along the lines of: "my hammer won't cock back when I pull the trigger, what's the problem?"

It was only a matter of time, but it happened to me. In this case on an m357 that I had tuned for my dad. Fortunately it only happened when I checked it after getting home so he's none the wiser.

So: any guesses for what went wrong here? (For what it's worth, I got it wrong.)

Here's a photo showing the maximum distance the hammer can be cocked:

.

Labels:

gunsmithing

Sunday, August 9, 2009

Saturday, August 8, 2009

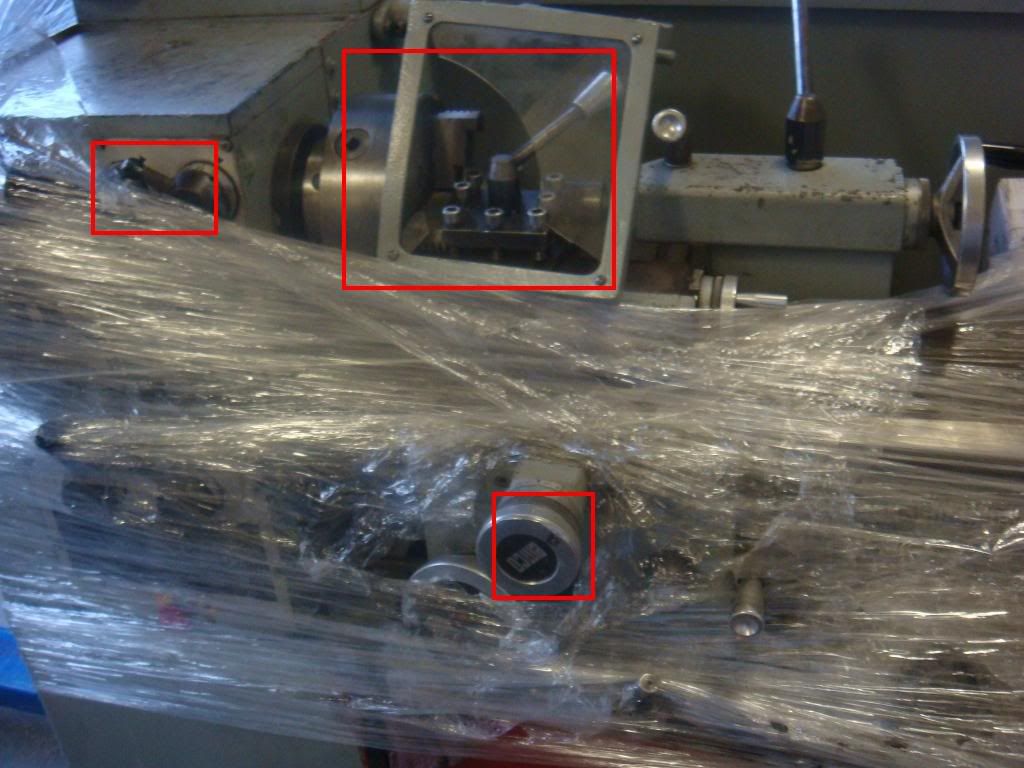

Damaged Emco V13 engine lathe

Photos of a Emco V13 engine lathe I received damaged by shipping on Friday. Looks like someone doesn't know how to handle their forklift.

In the shrink wrap, speed knob, crosslide knob, plexiglass and lateral wheel broken:

Sunday, August 2, 2009

looking for a spindle for a hardinge cataract toolroom lathe

I recently picked up a hardinge QC lathe. I finally got the time to use it today, but after a few cuts, the chucks wouldn't go on anymore. Looking closely at the spindle it seems there is a crack running the entire distance.

It seems like the spindle is cracked since this is a weird way to design something so important. If anyone w/ a hardinge QC toolroom could check theirs I'd appreciate it.

I'm also looking for backgears if anyone has them.

Labels:

machining

Thursday, July 23, 2009

stole a bison chuck on ebay!

NIB: $20 (+$19) shipping.

The only other one I saw was used, and $450. No idea why this one was cheap, but it looks fantastic.

There seems to be a 2 3/16 10TPI back that will fit it at: http://brassandtool.com/Backplate-Adaptors.html so we are close to liftoff.

Labels:

machining

Wednesday, July 22, 2009

Got the Hardinge Toolroom Quick Change lathe!

The hardinge lathe I bought last week finally showed up. The shipper had go use three different people before the final guy (a retired merch mariner) succeeded. He had to drive it up here since none of his employees wanted to deal with it.

According to helpful people on practical machinist it was made in the 1930s. It looks like the toolroom lathe on Tony's UK lathe site (http://www.lathes.co.uk/cataract/page5.html), but not quite as clean.

It was converted to 110v using a baldor motor. Theres a lot of tooling --- several live centers, collets, 3 and 4 jaw chucks, even comes with a spare baldor! According to the mover guy it looks like the owner built race cars --- you can see it was used for some heavy work from a few of the enormous tool bits. Seems like it may be sturdy enough for anything needed.

There's a couple of problems. First I have no manuals. If anyone knows of any writeups for how to use and care for one of these I'd be really happy to hear about them. Second I have to replace the belt. The mechanism the motor uses to rotate the belt (and thus the spindle) has a chunk missing on the outside. And a couple of screws seem missing from the spindle area. But, other than that, it's a very very good buy from what I can tell. The controls are lovely in person.

Spindle type seems to be 2 3/16 10TPI.

On the truck: the driveway is very steep, just missed bottoming out by 1 1/2". The lift gate wobbled like a boat bringing the lathe down: it's much heavier than it looks. They did not skimp on the iron:

Labels:

machining

Using screw extractors to fix bull barrel python

Thanks to some helpful suggestions, I was able to extract the broken screws on the bull barrel python discussed here: http://coltpython.blogspot.com/2009/07/fixing-misfires-in-41-mag-python.html

I went to OSH and get a couple screw extractors, used a drill, and the broken screws came out. And it was pretty easy.

Here's the patient for surgery with full contact restraints via a bi-lok CNC vise w/ aluminum jaws. You can see the extractor laying on the lower part of the vise:

Labels:

gunsmithing

Monday, July 20, 2009

how to break a bull barrel python

I have a bull barrel python that has a big aristocrat rib on it, seemingly setup for PPC.

I thought that this meant it was fine for near max 357 mag loads. Unfortunately I was informed that PPC ribs were in fact designed to keep the front sight on the X ring when doing powder puff 38spl loads and using them for 357 was going to cause problems.

This is unfortunate since I only learned this useful fact after the rib flew off my gun tonight and whacked me on the head when shooting 357. The empirical record suggests that the rib is fairly heavy, in case you were wondering.

Here's how things should look:

And like magic, reality shows how they actually look:

Labels:

forensics

Fixing misfires in a 41 mag python

[As always: this is just for entertainment purposes. If you do any of this t your gun it's going to get ruined! Note there are suggestions at the end of the post for things to do differently.]

I recently got a 41 mag python, which got dissected to see how Jack Huntington did the conversion (http://coltpython.blogspot.com/2009/07/forensic-photos-41-magnum-python-by.html). It had a lot of enshake which I fixed (http://coltpython.blogspot.com/2009/07/fixing-endshake-on-41-magnum-python.html). And while it didn't blow up after shooting a couple hundred rounds (http://coltpython.blogspot.com/2009/07/41-magnum-range-report-it-does-not-blow.html) it would also misfire about 1 round per cylinder.

The misfires were with large pistol CCI primers. I got told to just use federal, but that's cheating, so spent some time this weekend attempting to fix things.

The DA pull is around 6.2lbs, so it's possible that the mainspring is the problem. However, I've done colts that have a lighter pull and they've worked w/o issue, so the problem could be something else. Admittedly these other guns shoot 357, so perhaps the force needed to ignite small pistol primers is less than for large. However, I don't want to just blindly increase the mainspring as a way to mask any underlying issue.

To spare you the dynamic tension, in the end I did wind up increasing the mainspring by about 4oz but a lot of stuff got fixed along the way, so perhaps it's interesting anyway.

Just for reference here's the gun after the endshake fix:

A good colt smith gave a rundown of things to check for tracking down misfires, so we do some of those first.

Labels:

forensics,

gunsmithing

Friday, July 17, 2009

making a 50bmg barrel.

Not super detailed, but interesting nonetheless: http://www.riflebarrels.com/articles/50calibre/chambering_50cal_rifle_barrels.htm

Labels:

gunsmithing

More Randy Lee on hammer mass and firing pins

http://smith-wessonforum.com/s-w-smithing/90499-my-thoughts-firing-pin-length-ignition.html

I need to track down the rest of his posts. But anyone that gets reliable guns at a DA pull of 3lbs needs to be paid attention to.

Hat tip: Paul D.

I need to track down the rest of his posts. But anyone that gets reliable guns at a DA pull of 3lbs needs to be paid attention to.

Hat tip: Paul D.

Labels:

gunsmithing

Thursday, July 16, 2009

WSJ picks of top econ blogs

http://online.wsj.com/article/SB124768581740247061.html

I'm slowly working my way through. Of the first few, this one seems the best: http://www.calculatedriskblog.com/

I'm slowly working my way through. Of the first few, this one seems the best: http://www.calculatedriskblog.com/

Labels:

current events,

not-blam

just got a emco (not enco) compact 5 CNC!

I just got an emco CNC compact 5. The good news is that the thing actually works, despite the cheap price. The bad news is that it's the first generation so doesn't even have a place to plug in a cable to the computer.

"Suboptimal" is a charitable view of this setup.

I can't seem to find a reasonable 3 jaw chuck so had to go with collets instead.

In relief news I was able to figure out most of the 12 simple (g code) commands it provides. The manual I have seems to be for the latter versions, so a bunch of stuff they do does not work on mine. Like deletion.

So now I can make it go back and forth, in circles, and other fairly rudimentary geometric shapes. Nothing that would make Euclid interested, but still.

Useful machining techniques.

Cute trick: stick drill chuck into lathe headstock to make poor man's collet holder. Surprisingly good runout.

http://www.astronomiainumbria.org/advanced_internet_files/meccanica/easyweb.easynet.co.uk/_chrish/techindx.htm

http://www.astronomiainumbria.org/advanced_internet_files/meccanica/easyweb.easynet.co.uk/_chrish/techindx.htm

Labels:

machining

Wednesday, July 15, 2009

Tuesday, July 14, 2009

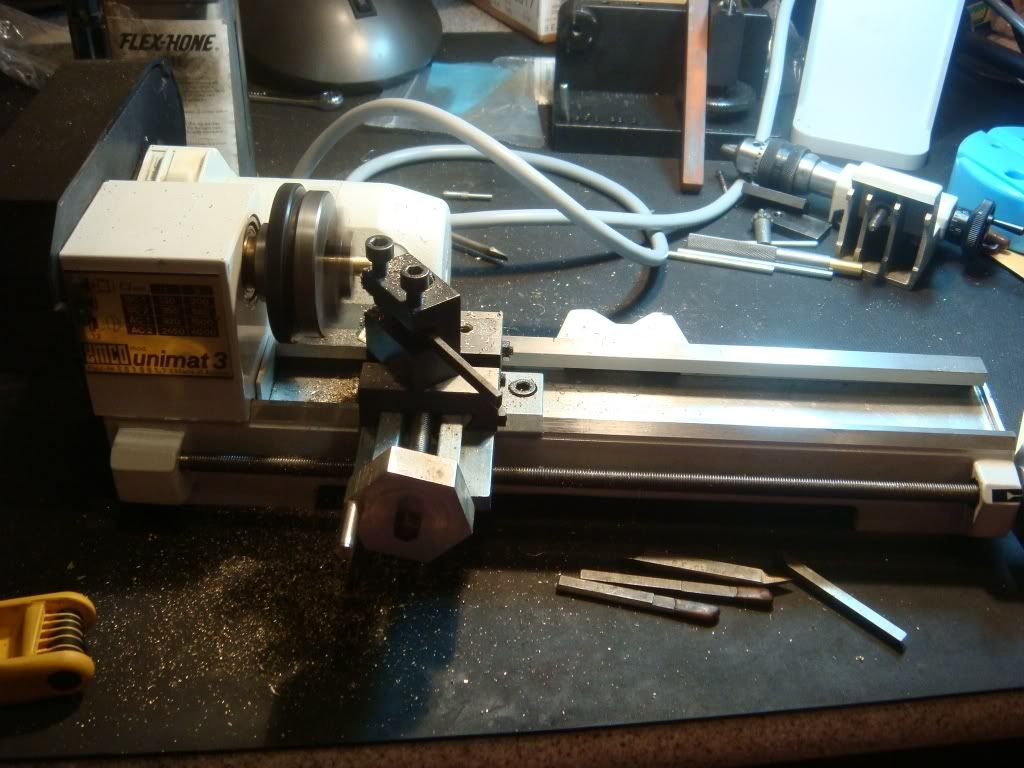

Finally: unimat 3 is up and running.

Finally, my unumat 3 is running. I didn't know much about them when I bought it on ebay and it turns out it had been completely stripped of all needed parts, other than the motor. Finally got the belts today, so put them on, fussed with some other stuff longer than needed (I have the manual, but it remains unread) and then started cutting.

I got 40lbs of carbide lathe tools very cheap recently, and fortunately a bunch of them seem to more-or-less fit the tool holder.

It's so small I'm not quite sure how to use it for colts, other than making slightly larger than stock rebound pins for guns that have expanded holes.

Here it is making nothing in particular besides brass shavings:

Subscribe to:

Posts (Atom)