To be successful in one of the most challenging handgun matches currently being competed—the Masters International Long Range Handgun event—shooters are turning to a heavily modified version of a now-defunct gun model. The base model, no longer being manufactured by Remington Arms Co., is the XP-100; the tricked-out XP-100 that makes it possible to hit and knock over 6-inch, 9-inch, and 12-inch steel plates at 200 meters is made by Accuracy Unlimited, Frank Glenn’s precision-gunsmithing firm based in Glendale, Arizona.

Glenn’s gun is dominating the Masters Long Range Handgun event because it is uniquely suited for the difficult course of fire. Sixty seconds are allowed for five shots on five steel targets and ninety seconds for ten shots on ten targets some of which weigh as much as 23 pounds. The event is run in six strings of fire, three of five shots in 60 seconds and three of ten shots, at alternating distances, in 90 seconds. One shot is allowed for each of the total of 45 targets. The distances include targets at 75, 100, 150, and 200 meters, and the first fifteen and the last five targets must be shot from an offhand (standing) position. The middle 25 shots are freestyle. If the course of fire isn’t challenging enough, there is also a significant noise factor in the event. While you are shooting your handcannon, eleven other people are doing the same thing. Besides the incredible noise level, each shot from your gun and that of the other eleven shooters hits you with a concussion you feel throughout your body.

Glenn’s XP modifications don’t make the targets bigger, the wind settle, or the muzzle blast lessen. But they can make a handgun accurate and shootable enough to knock over 42 of 45 steel targets, as Jerry Barnhart did in 1994, or to drop only four targets, as I did in 1995. They are also a kick when used to hunt prairie dogs, which can hone your ability to judge distances and shoot from difficult positions. Here’s what Glenn does to the XP-100 to make it perform at top levels.

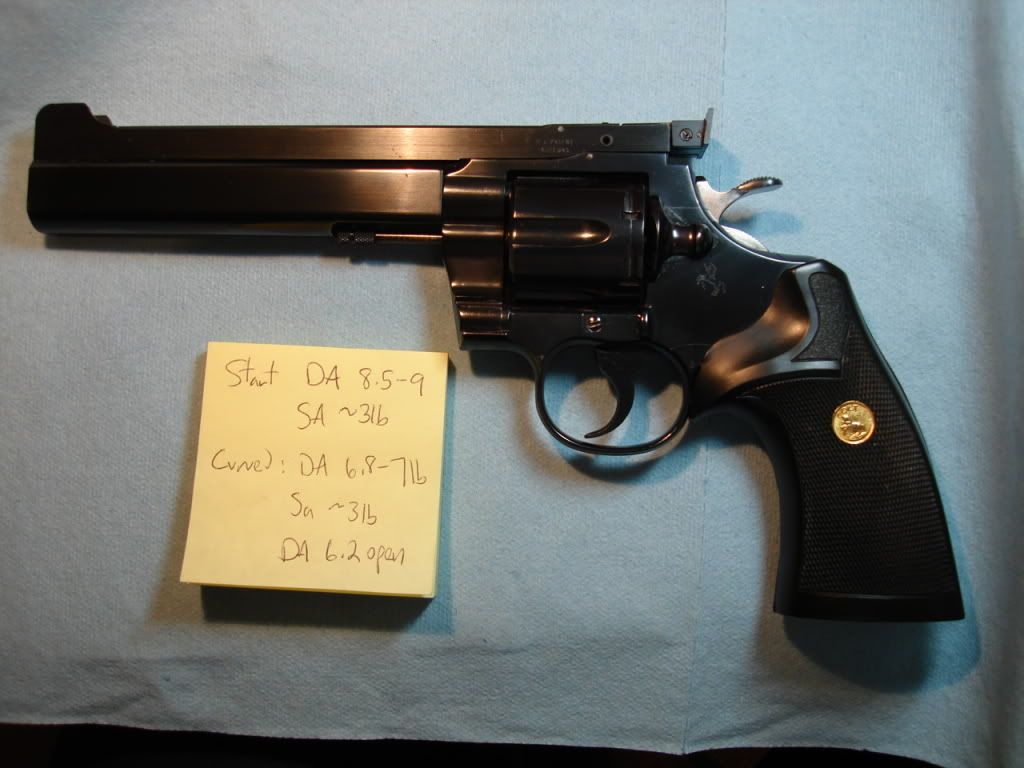

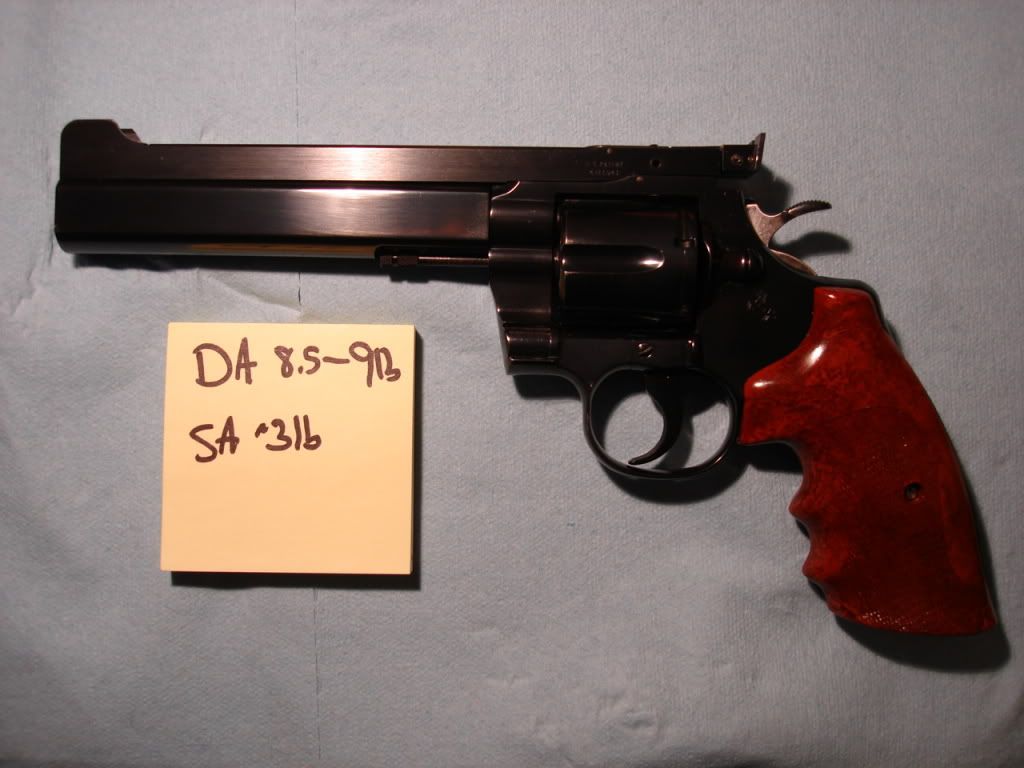

The Forward Grip

Some shooters use the standard XP stock, which is called a center grip, for competition. It’s terrific for shooting from the Creedmore or other rested position, but it is difficult to stabilize the gun when it is shot offhand. Others have tried the Thompson Center Contender, which has a rear grip, and discovered the same results. It is easily stabilized from a rest, but wobbly offhand.

Glenn started modifying the XP’s grip after he and other top Masters competitors got tired of practicing on the Long Range event targets and took out their .38 Super action pistols to play. After a few shots, they found their holds and could reliably hit the 12-inch targets at 200 meters. “Then Brian Enos commented that maybe the grips were on the wrong end of their guns,” Glenn said. “I went home thinking about the comment and commenced to cutting up some center and rear grip stocks and then whittled a prototype out of a 2- by 8-inch chunk of maple.”

Thus the forward-grip stock was born. It allows the placement of both hands on the one grip that extends below the stock and allows the rear of the gun, where the bolt and chamber are located, to rest on the shooter’s forearm. “I took this sample stock to the SHOT Show in 1989 to get the impressions of Enos, J. Michael Plaxco, and some other shooters,” Glenn said. “There were favorable opinions expressed because of the stability offered by the stock.”

The forward grip stabilizes the gun, but there are some tricks to shooting it well. First, the shooter must not apply pressure to the grip. It is vital to allow the gun to simply rest in both hands. Applying muscle to the gun makes the rear of the gun jump during recoil because tensing the forearm muscles makes the gun move.

The next trick is to form a flat platform upon which to rest the stock. This is done by holding the strong hand out at arm’s length with the fingers spread and the palm facing inward, and then rotating the palm upward without bending the elbow. Paying special attention to the forearm, make sure the muscles have rotated and you will see that an area that was formerly about 30 degrees off horizontal, just forward of the elbow, has now become parallel to the floor. This is where the rear base of the stock will sit. Now rotate the hand back to the shooting position moving only the forearm, not rotating from the shoulder, and the position is complete.