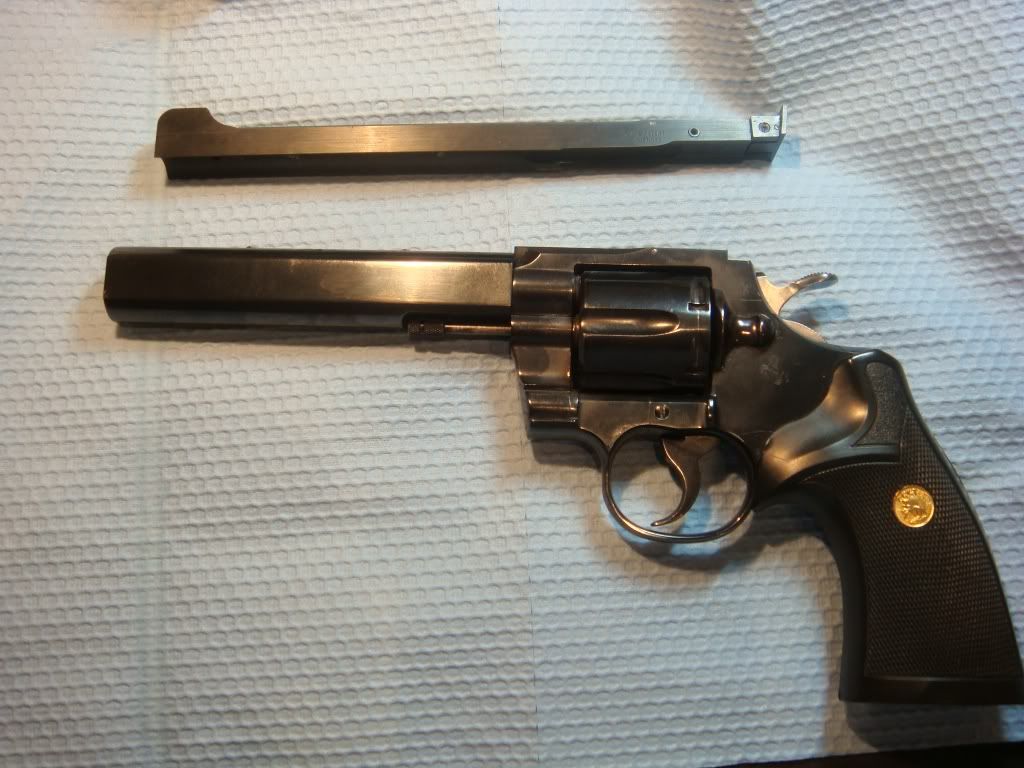

I got a 41 magnum python conversion a while back, but unfortunately hadn't been able to shoot it b/c of excessive endshake. The difference between the max and min barrel / cylinder gap was well over .005 and, even worse, the minimum barrel / cylinder gap was about .00025 which made it seem likely the cylinder would slam into the barrel.

This weekend I finally got a chance to fix the problem by cutting out the cylinder, machining a bushing and putting it all together (with a bunch of fitting). I first did two shooter model 357s for practice (it won't be an easy matter to replace a jacked up 41 mag python cylinder) and then did the 41 magnum.

The process was not entirely smooth: I had to rip one bushing out and start over and the fitting was made excessively tedious since I did not record the minimum barrel/cylinder gap measurement before cutting out the cylinders. However, in the end all three colts now have < .001 endshake. Of course, they need to survive a bunch of rounds before declaring success. But, that's why god made next week :)

In promising news I've already done the identical fix to two pythons and a trooper when I went out to visit Frank Glenn. For these three colts it seems that things were done right: when I finally did a range test last week they survived 500+ rounds between them without issue. (They seem smoother too since they started at close to .0000 endshake, which forced the cylinder to travel through any binding rather than slip around it.)

OK. So let's get to it. We get excessive endshake when the collar on the cylinder is too short, and thus allows the cylinder to travel forward too far. You can stretch the collar using a special fixture but, unfortunately, that's a one time fix. We instead replace the collar by removing it and putting in a bushing in its place: you remove endshake by making the bushing sufficiently long.

Our algorithm:

- Measure headspace to make sure we are comfortably above the minimum. If not, we can't do this fix (and likely will have to replace the ratchet).

- Take the cylinder apart completely.

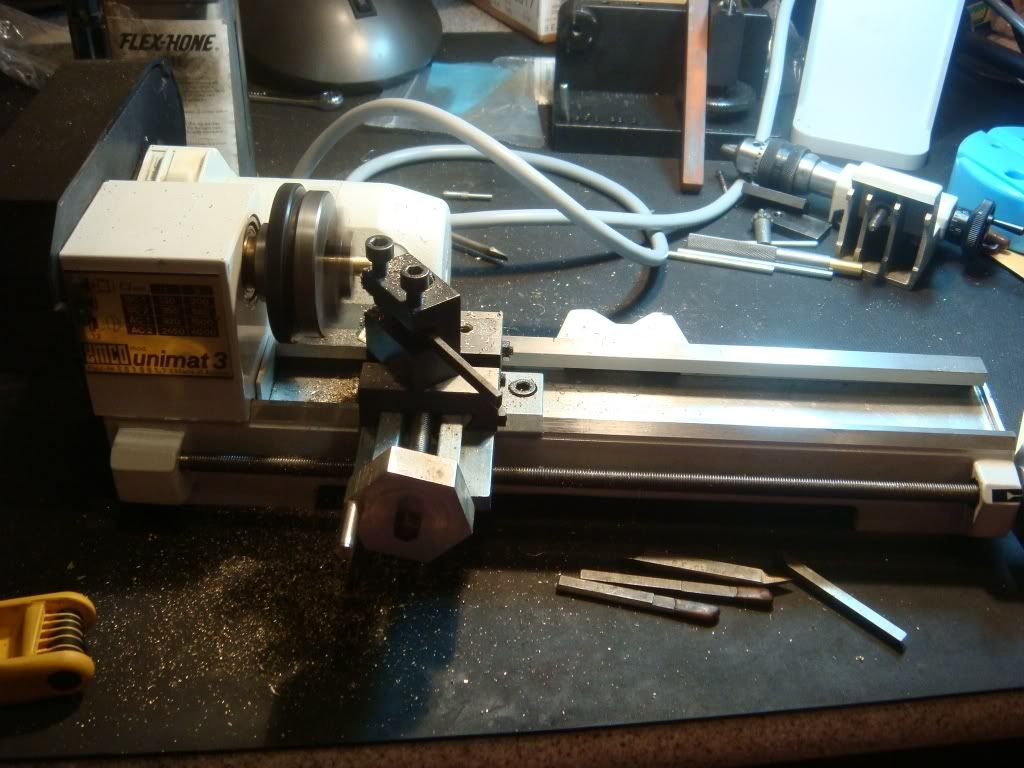

- Put the cylinder in a 4 jaw chuck in a lathe and use an indicator to ensure that as it spins it wobbles by less than .0005".

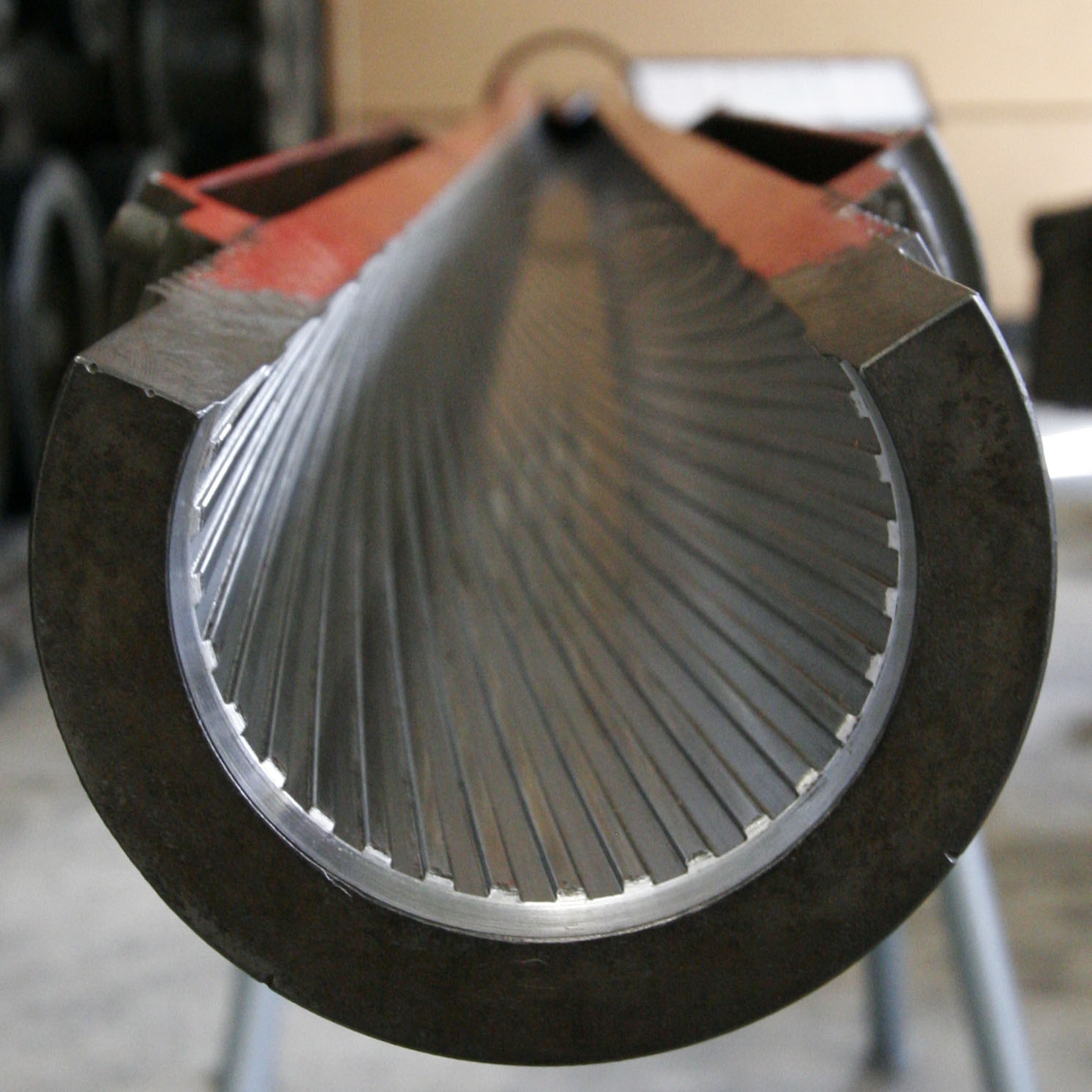

- Use a boring tool to cut a hole where the collar is until all (or just about all) of the collar material is removed.

- Construct a bushing that reaches the bottom of the hole and has has a wide enough diameter so we can press fit it in the cylinder. The "collar" sticking out needs to be thinner than this part so it does not contact the barrel.

- Press fit the bushing in.

- Slowly remove material from the collar until the cylinder will fit in. Slowly remove more until it will turn. Be careful: just b/c the cylinder isn't turning doesn't mean the bushing is too long! It could be that 0 endshake is exposing other sources of binding.

We'll step through each step.

Cutting collar

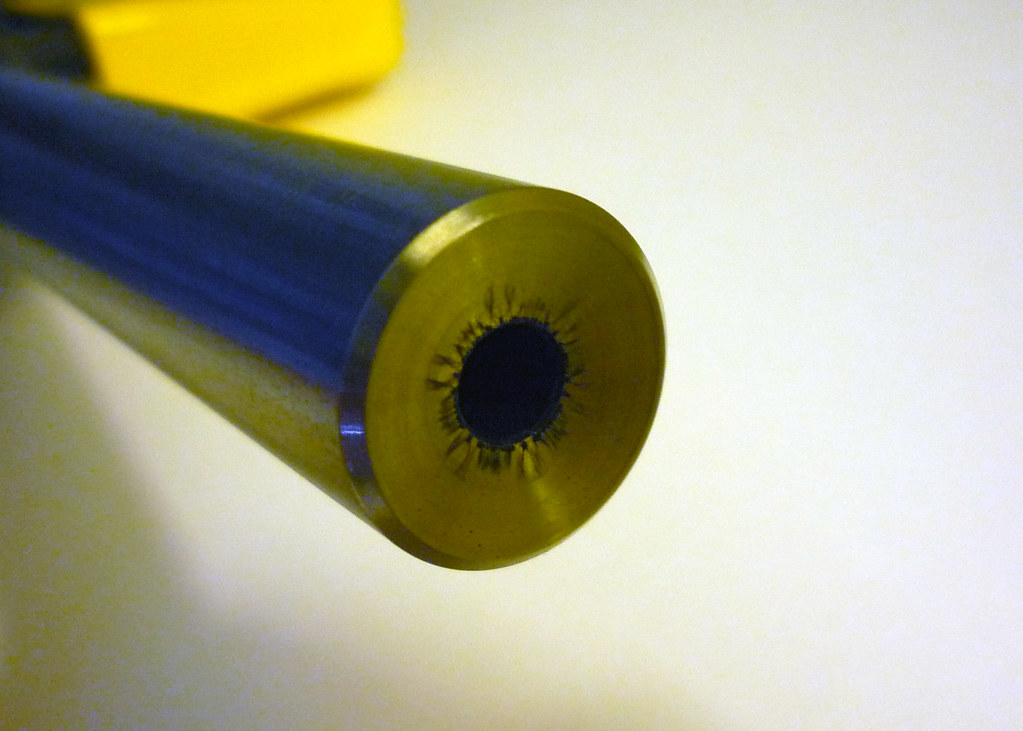

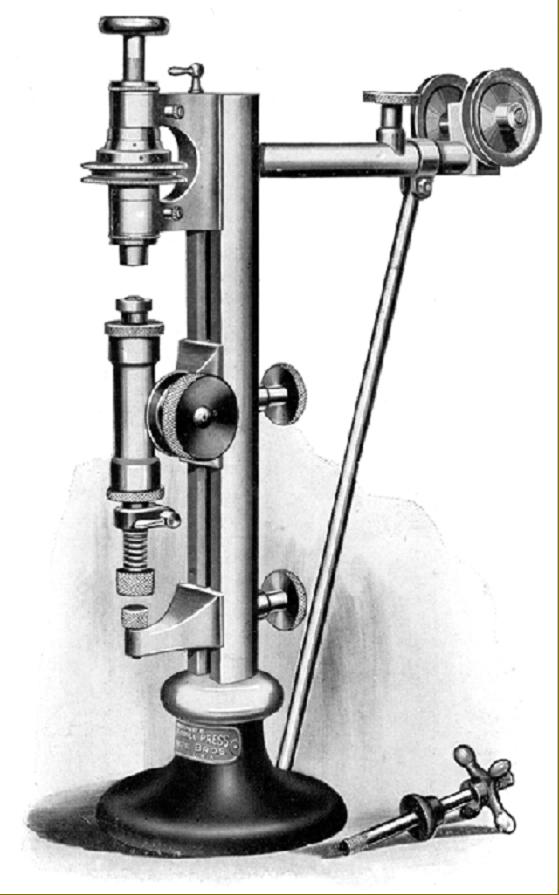

Here's the cylinder and the carbide tipped boring tool we're going to use to cut out the collar and make a flat bottomed hole: