There's been a bunch of threads on the Walt Sherman "roller action" where he used a ball bearing to reduce friction in double action. Unfortunately there hasn't been much detail. So to fix that we now err on the excessive detail end of things.

I bought a purported Sherman Officer Model Special (OMS) in 38spl a while back with Fishpaw grips, but hadn't had the courage to open it up.

Well that changes now! It was a pretty interesting set of internals that were in the gun.

Outside

Here's the outside:

And a bit of Fishpaw porn:

As you can see OMSes, like the later model 357s, had their lower surfaces bead blasted:

The inside has the date and various stamps. Fishpaw runs the screw through a brass bushing between the two panels:

Really nice quality grips. I assume it doesn't make sense to shoot with them on, but ...

Sherman Mainspring tricks

OK. Let's get to the main event.

Even with just the grips off things get intriguing. Sherman did an interesting trick for the mainspring where he kinked up the lower leg so that the distance between the two ends is roughly what it would be stock:

This seems (potentially) to be at least a partial solution to the bad returns / sloppy action you make the action particularly light by bending the spring in the traditional way: doing so makes the jaws of the spring closer, which seems to make the hammer bounce about a bit and the return mushier. It may be that Sherman's way lets you reduce the pull yet still keep things crisp. More experiments TBD.

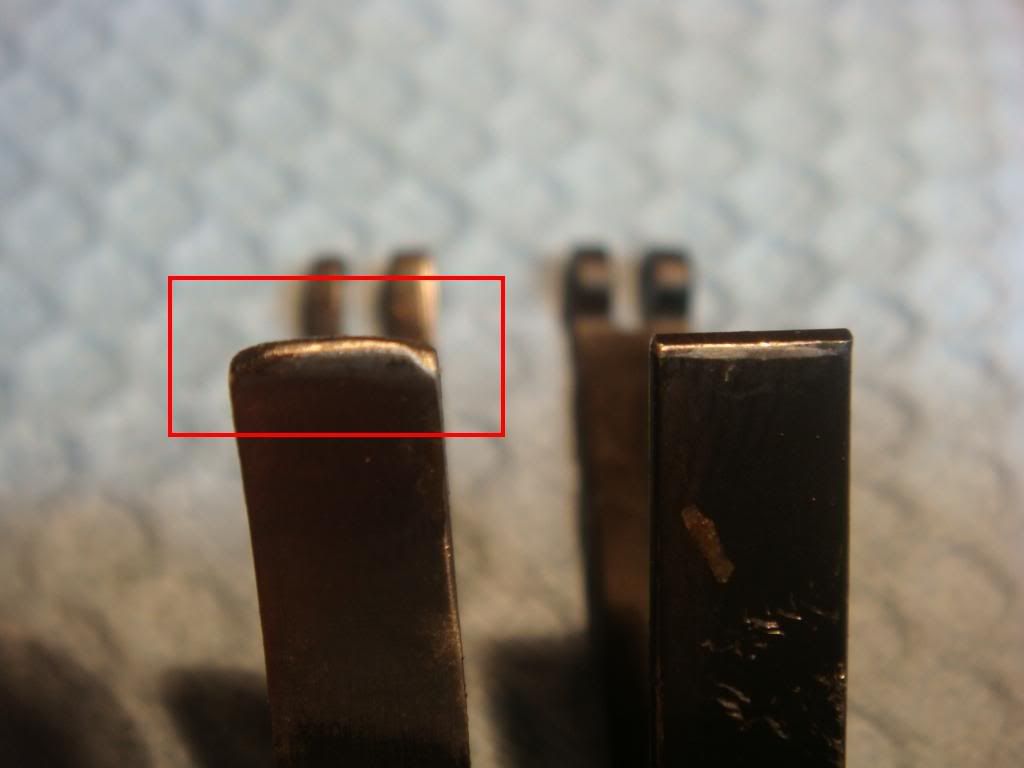

Here's his (middle) compared to a normally modified one (bottom) and one that is more compressed (top) on the 41 mag python done by Jack Huntington:

The spring has some interesting polishing I don't recall seeing before. The end of the lower leg has been polished, presumably so it slides smoothly on the rebound lever. Here's the Sherman spring (left) vs standard (right):

Close up:

The other end also looks polished:

Sherman Action

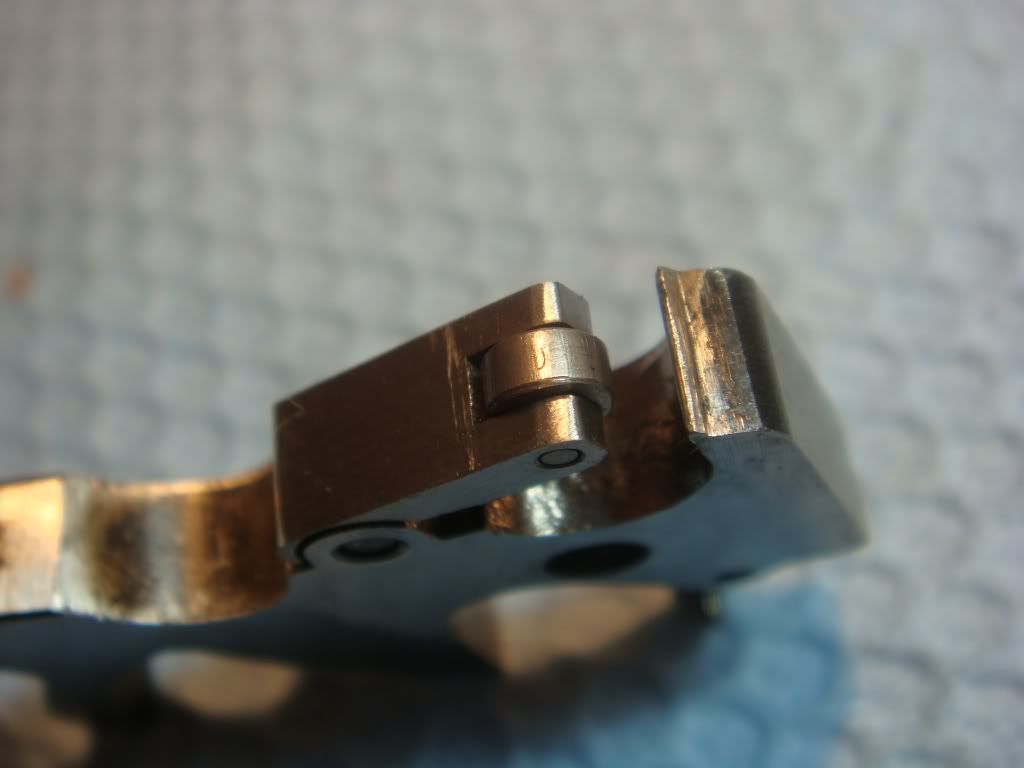

Popping off the side plate there is major relief: It is a Sherman! The ball bearing has been put on the end of the hammer strut so that when you pull the trigger there is less friction:

Closer views from various angles:

And now comparing to a stock OMM hammer that still has cosmoline on it:

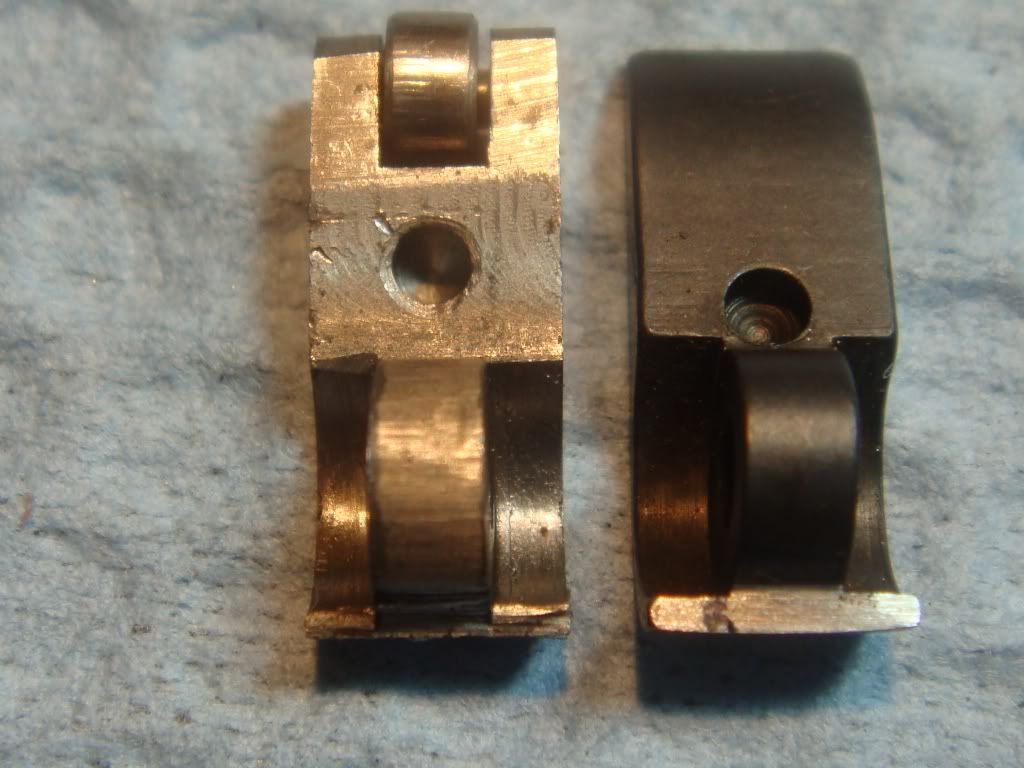

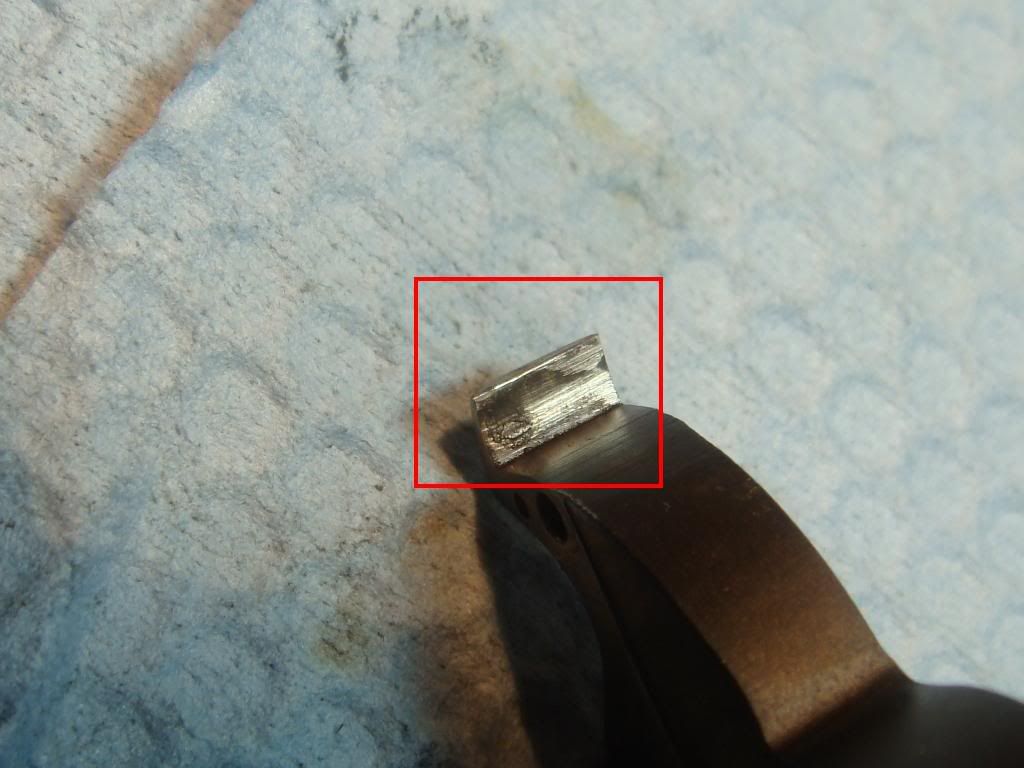

After removing the modified strut from the hammer we can compare it (right) to a stock strut (left). Left side of struts:

Closer left:

Front of struts:

And reversing, here's the back Sherman (left) stock (right);

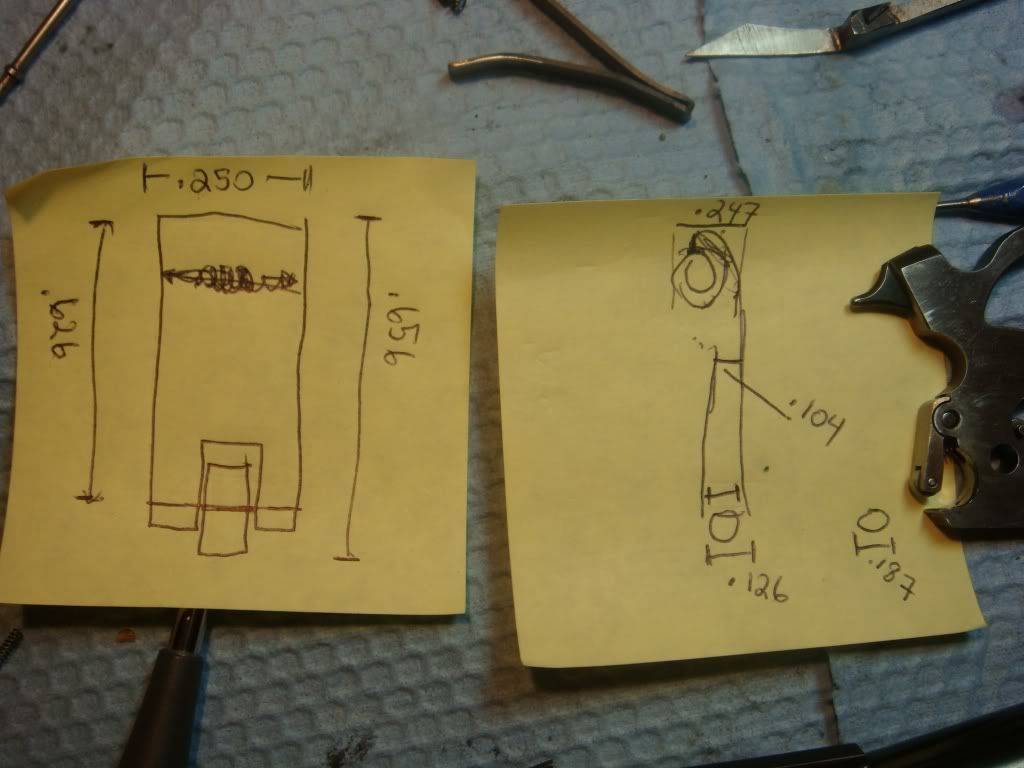

Taking dimensions of strut and bearing (maybe boring)

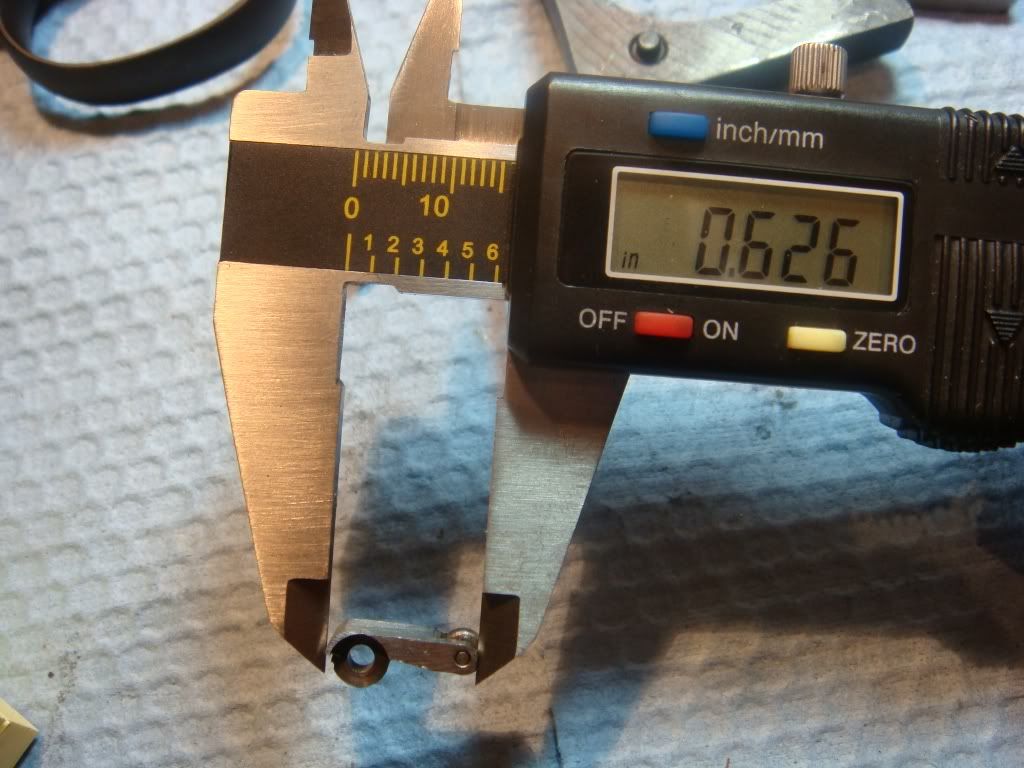

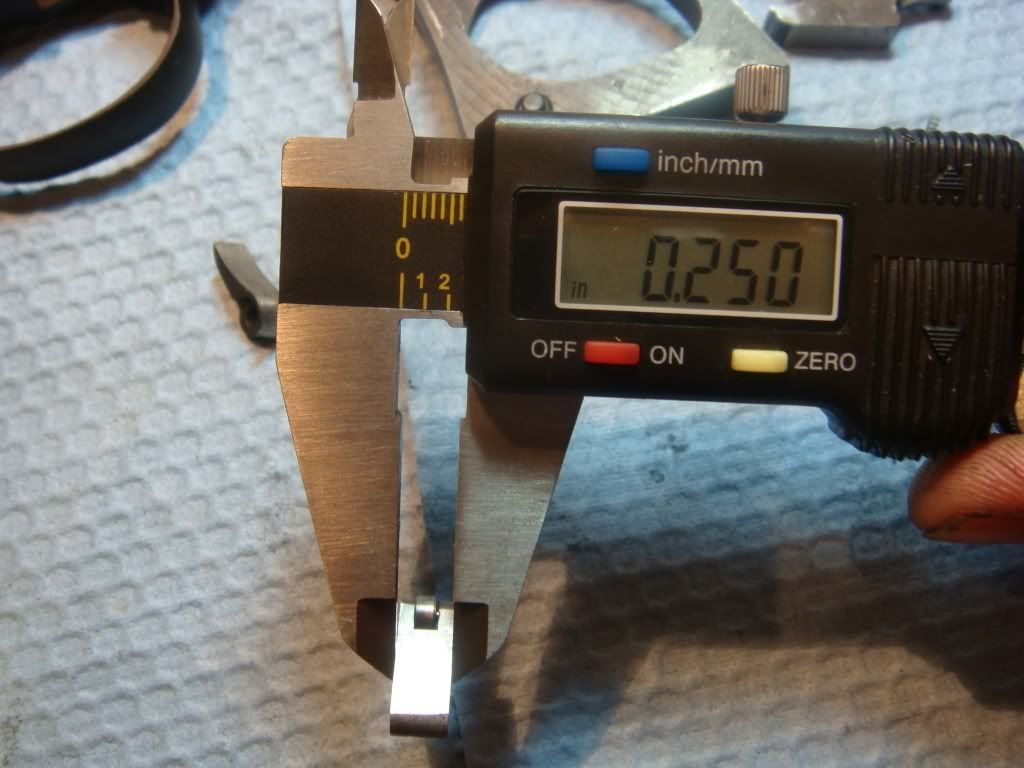

Just so we can build it, we take crude caliper measurements.

Length is ~.626":

Strut width is ~.250":

Strut thickness at bottom near bearing is ~.126":

Thickness at towards top (thinner) is ~.107":

Strut thickness at top where strut pin goes through is ~.247":

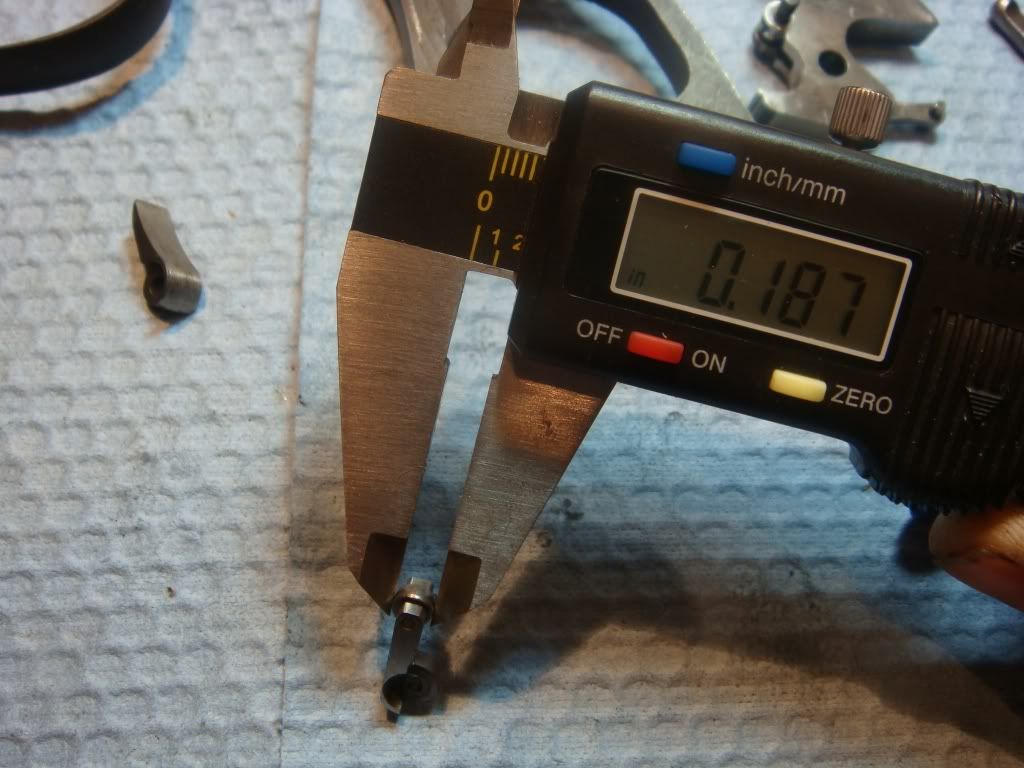

Thickness of bearing is ~.187":

It's great the OD of the bearing is .187 since that's the size of the roller bearings I'd ordered previously:

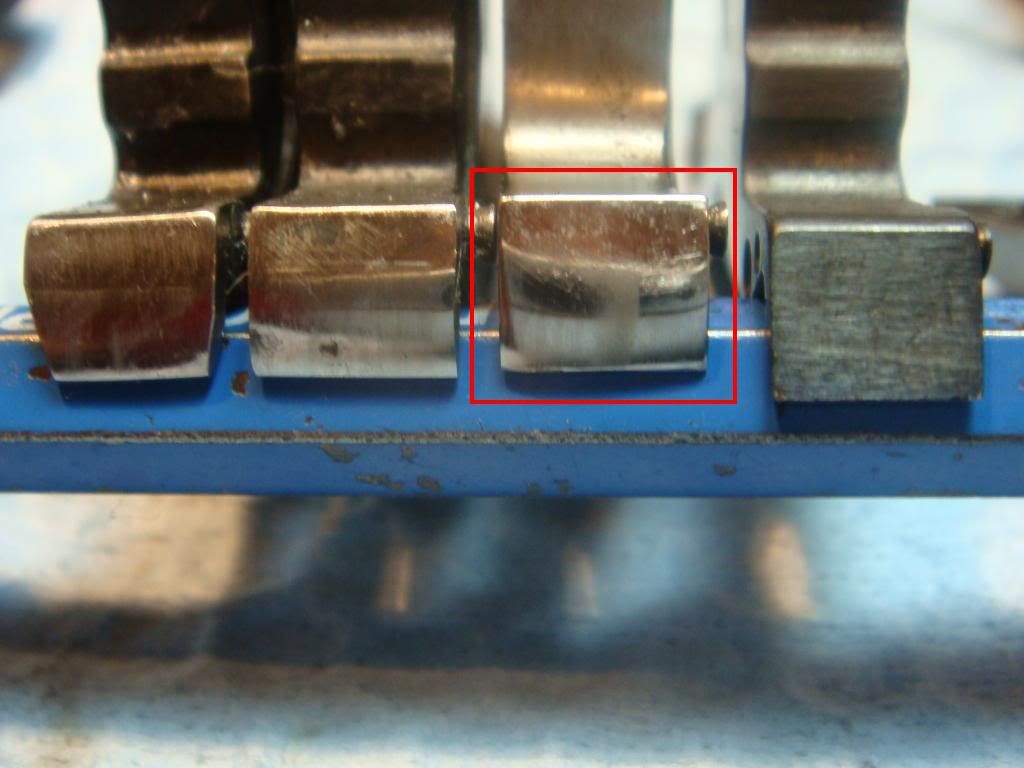

However, the internal diameter (ID) is definitely different on the Sherman. It looks like, close up, that this might not even be a bearing, but may in fact just be a cylinder. I didn't want to pop the pin off and potentially ruin the gun so left it be. If you look from the side you can see at the very least he used a different type of bearing:

Curved sear trigger

As everyone knows by now, you eliminate stacking in a colt by curving the sear

on the trigger: use a torch, bend, let cool, polish. This is what Sherman

did.

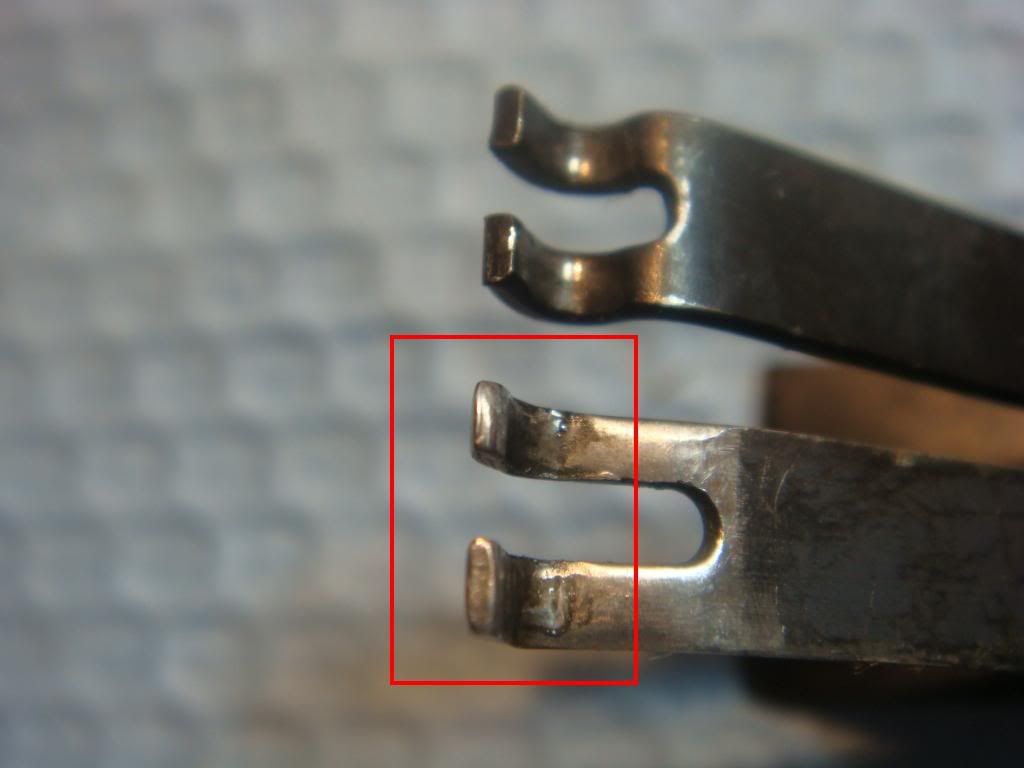

Here's a set of triggers. Top left is stock, top right is Jack Huntington,

bottom left is a Frank Glenn trigger and bottom right is the Sherman:

As you can see, the Sherman and Glenn triggers are very similar (and hopefully

I didn't swap the labels since I didn't mark things!)

Here's things from the front. From left to right: Huntington (note the

bevel), Glenn, Sherman (note the bearing wear mark), and stock.

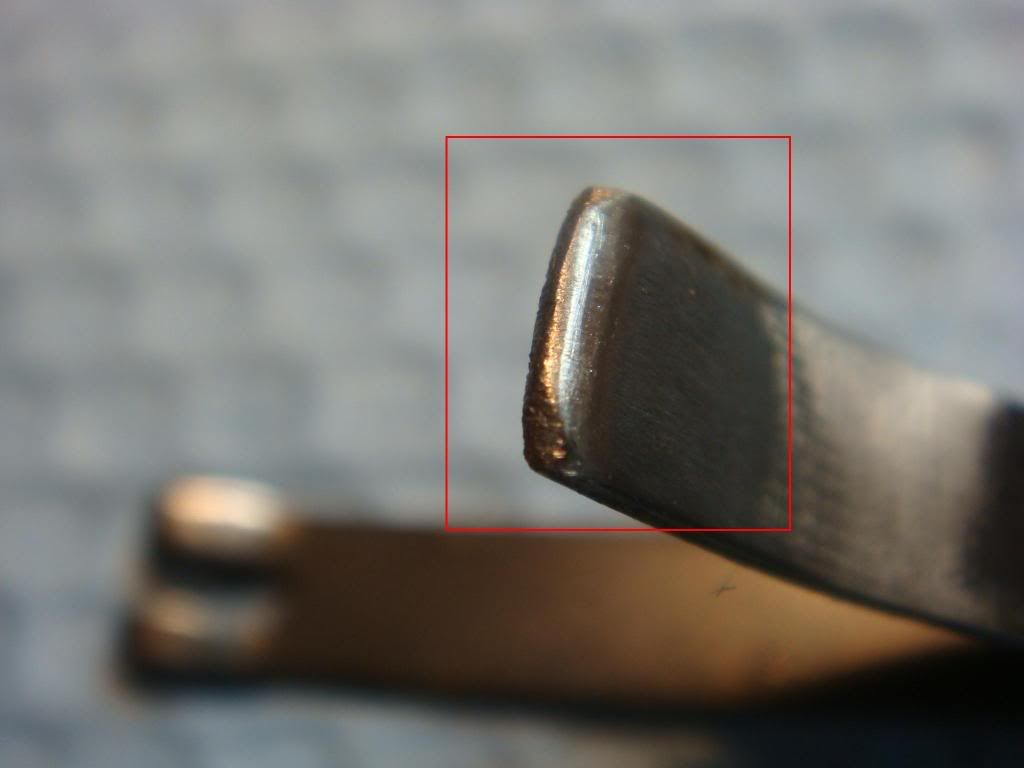

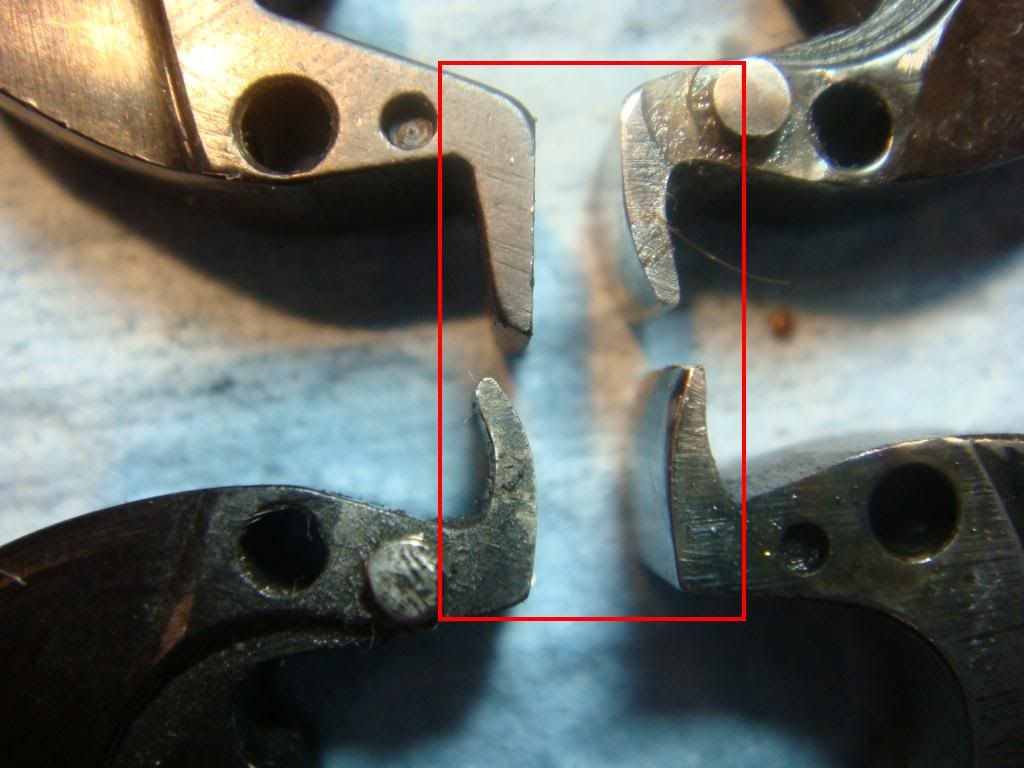

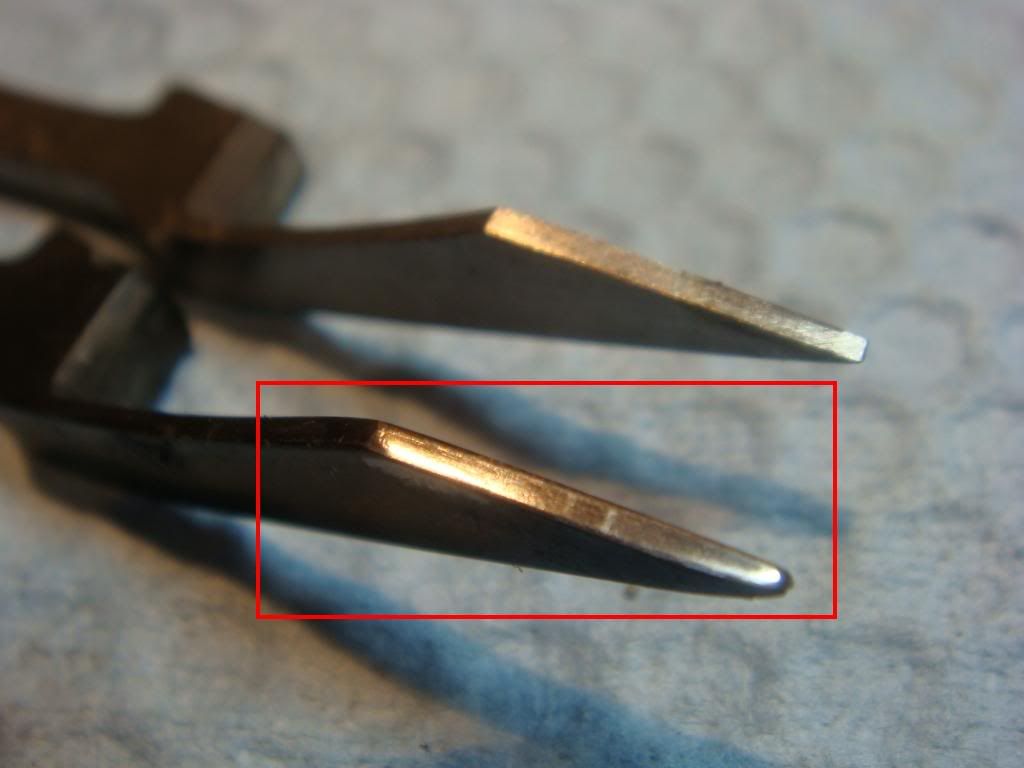

Looking closer, Sherman (left) polishes the end to more of a taper than Glenn

(right):

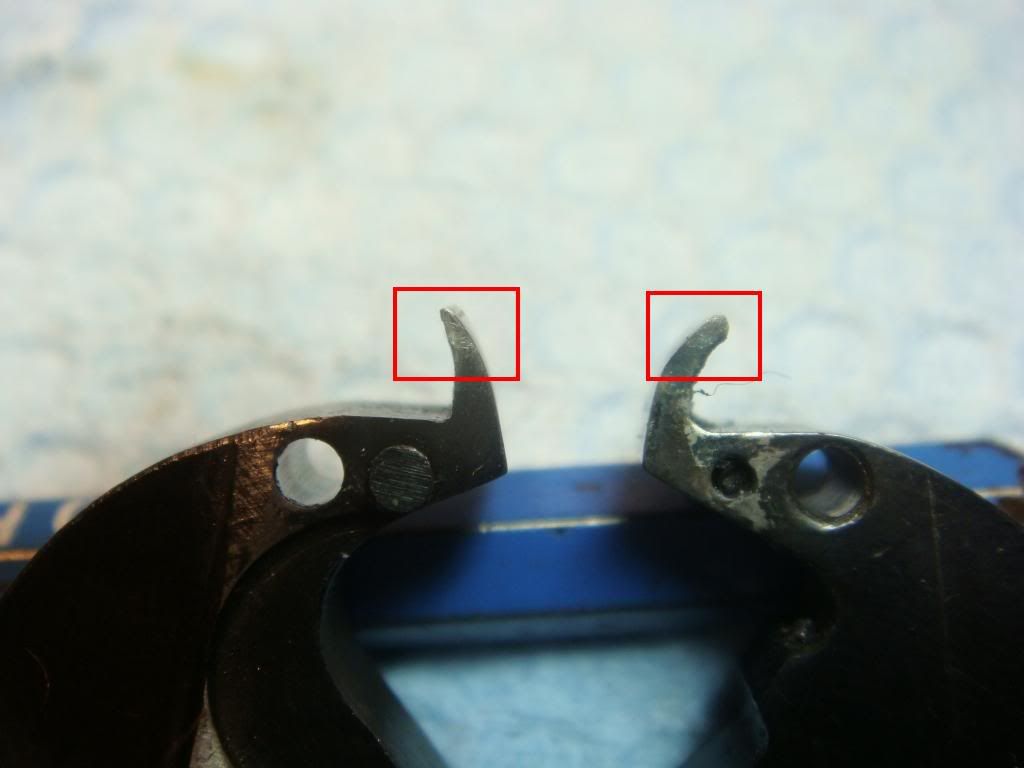

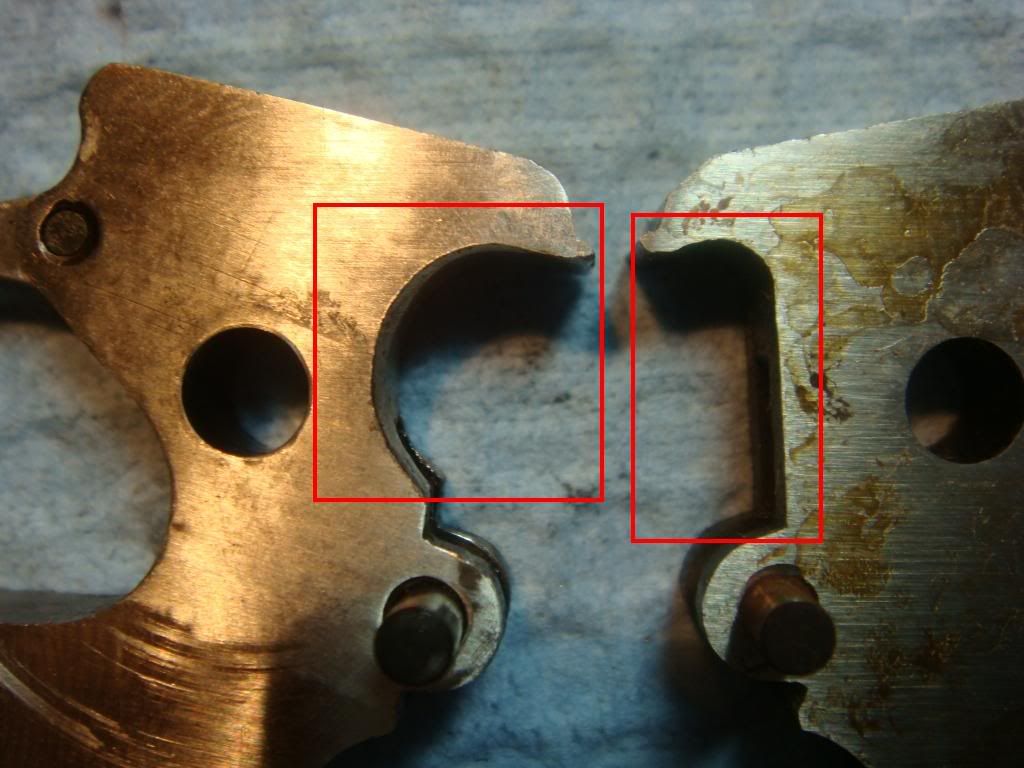

Often if you bring a colt sear to a point it'll make the SA pull worse since it will get lodged deeper in the cocking notch. In this case I think he's modified the notch enough that this doesn't happen (there also seems to be a bit of a bevel on the sear). Here's the modified hammer (left) vs stock (right). When people talk about altered cocking notches on the hammer, they mean something like this:

Sherman (top) stock (bottom):

Note that the notch hasn't been filed evenly. This is a pretty crude mistake, so I'm wondering if he did this on purpose?

If you put in a curved sear trigger it's hard to have a relatively low SA pull and/or no creep if you don't fuss a bit with the notch. For normal triggers, it is strongly NOT RECOMMENDED.

While the rough geometry of the triggers is the same, looking more closely it seems that the Glenn trigger curves more. We check this by putting the Glenn trigger in the Sherman gun and find that Glenn's trigger does curve more since the hammer strut cannot reset after firing:

(Note that like the Huntington gun, the Sherman also will not reset w/ the rebound removed, but does with the rebound and hand in place.)

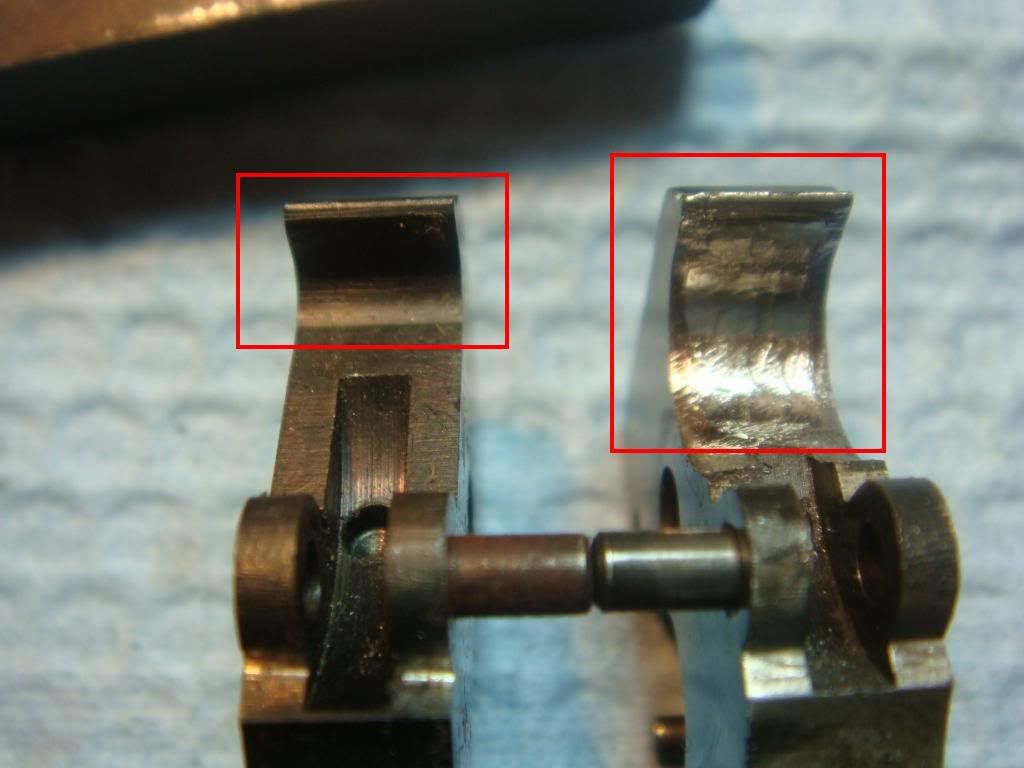

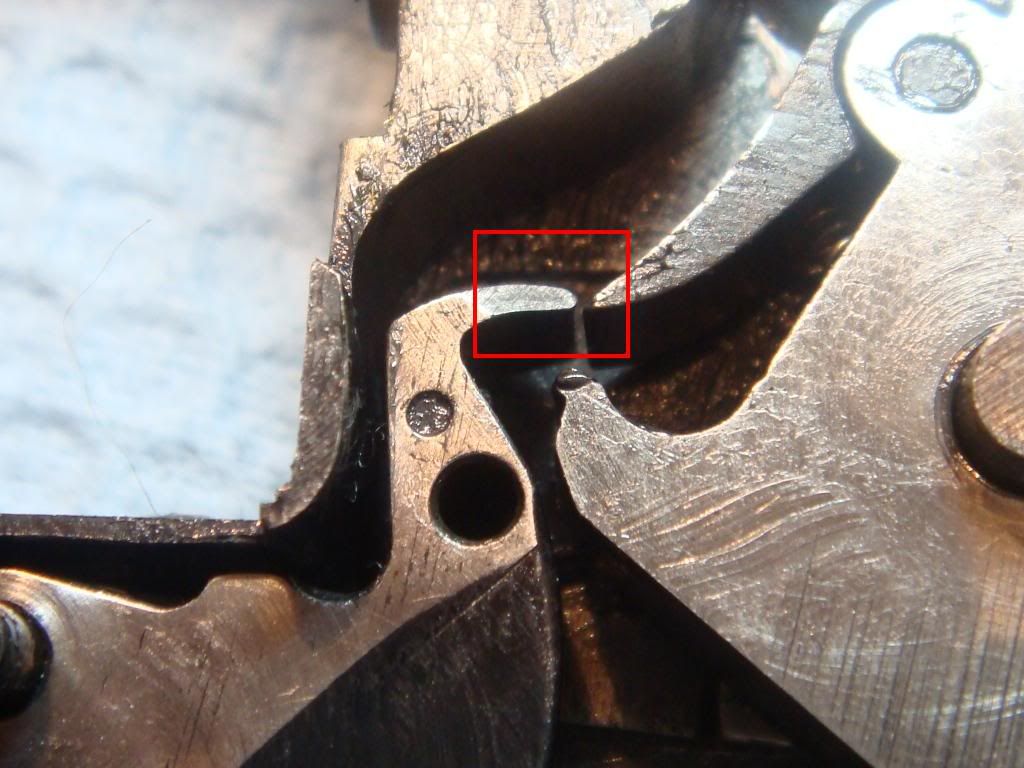

If you look closely, it seems that the Sherman sear has a flat spot at the beginning (left), so doesn't go as high as Glenn's (right):

It seems Sherman did use a torch since he had to polish the bottom a bit:

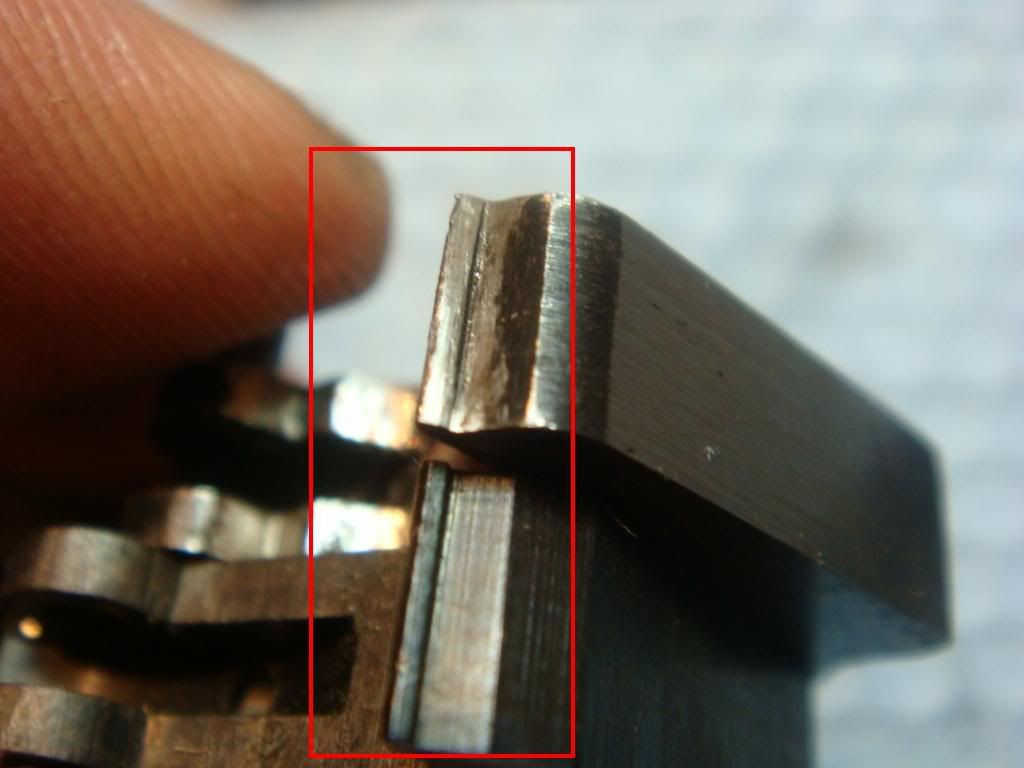

Since the sear is curved, the trigger will be canted forward and higher if you don't cut a groove in the hammer toe. Usually you do so with a file. From looking at Sherman's hammer he used a tool (possibly even a dremel, given the unevenness of the marks!). Here's Sherman (left) vs stock (right):

And from the front:

Hammer release

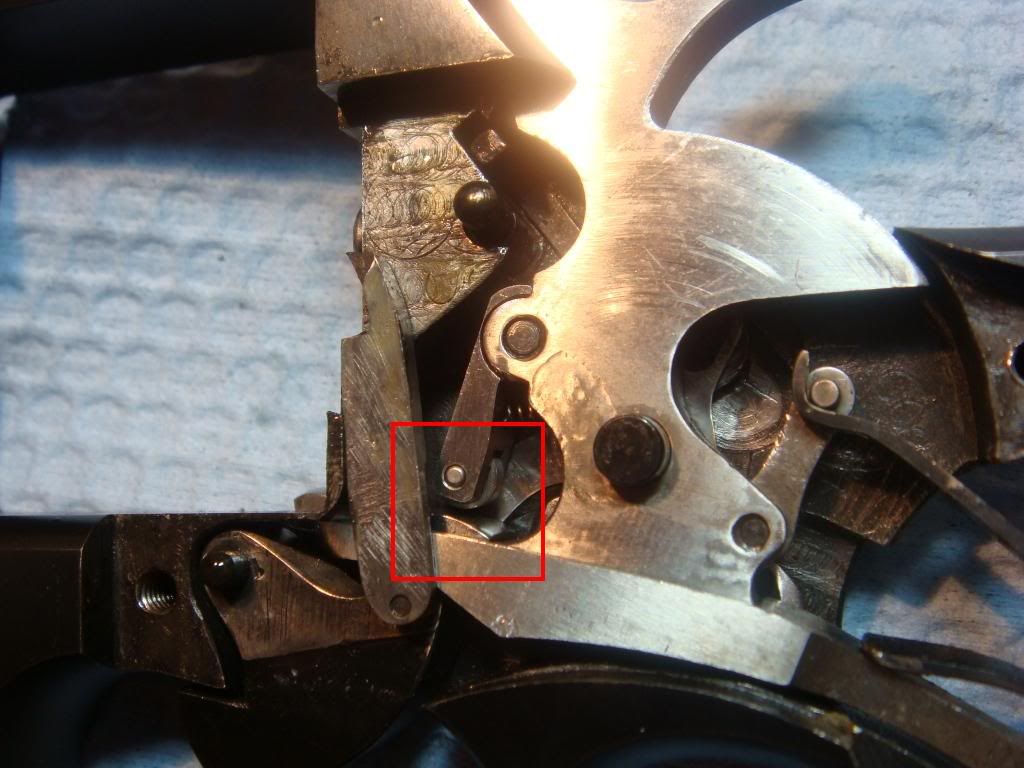

Finally, hammer release with the bearing in place was the thing that was puzzling me for awhile: the bearing makes the strut stick out farther, which means that it will contact the sear as the hammer falls forward if you set things up as usual.

It turns out this is exactly what happens but it doesn't matter: b/c the bearing slides by the strut you don't feel the heavy bump you would if it was a normal unmodified hammer strut hitting it.

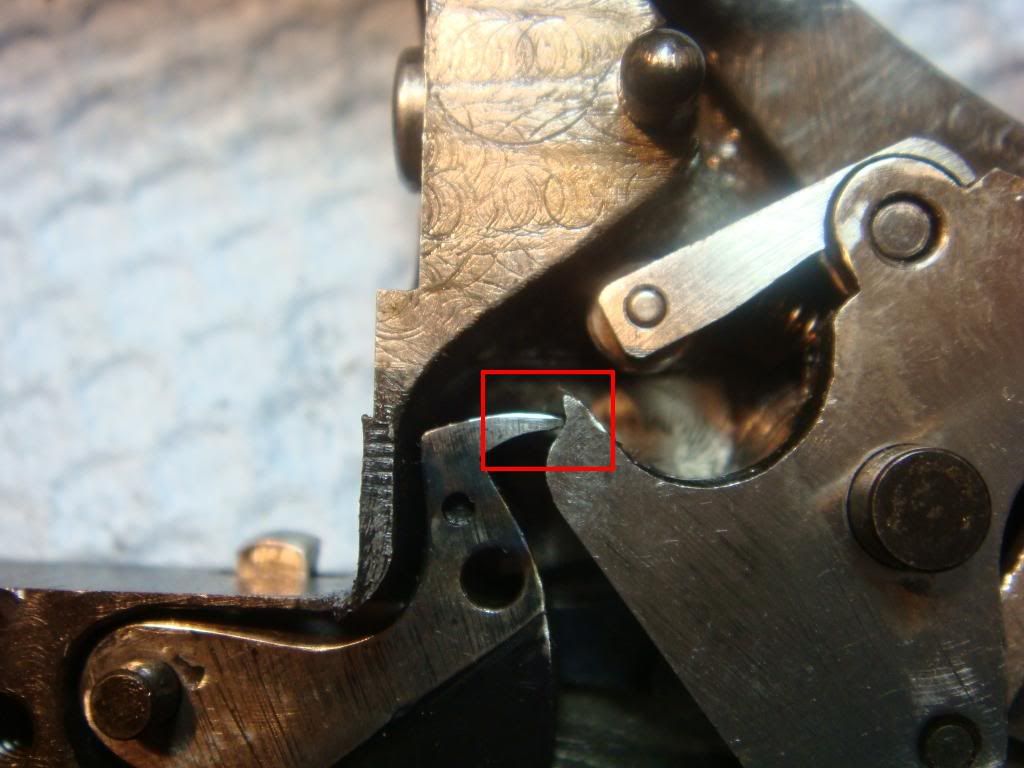

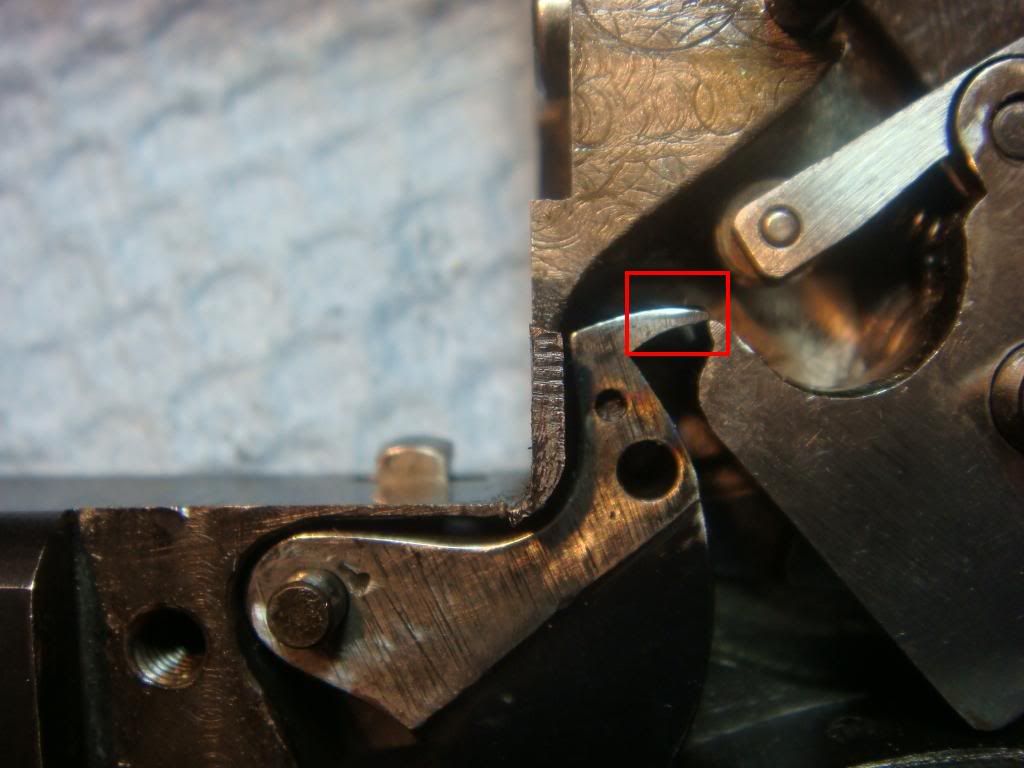

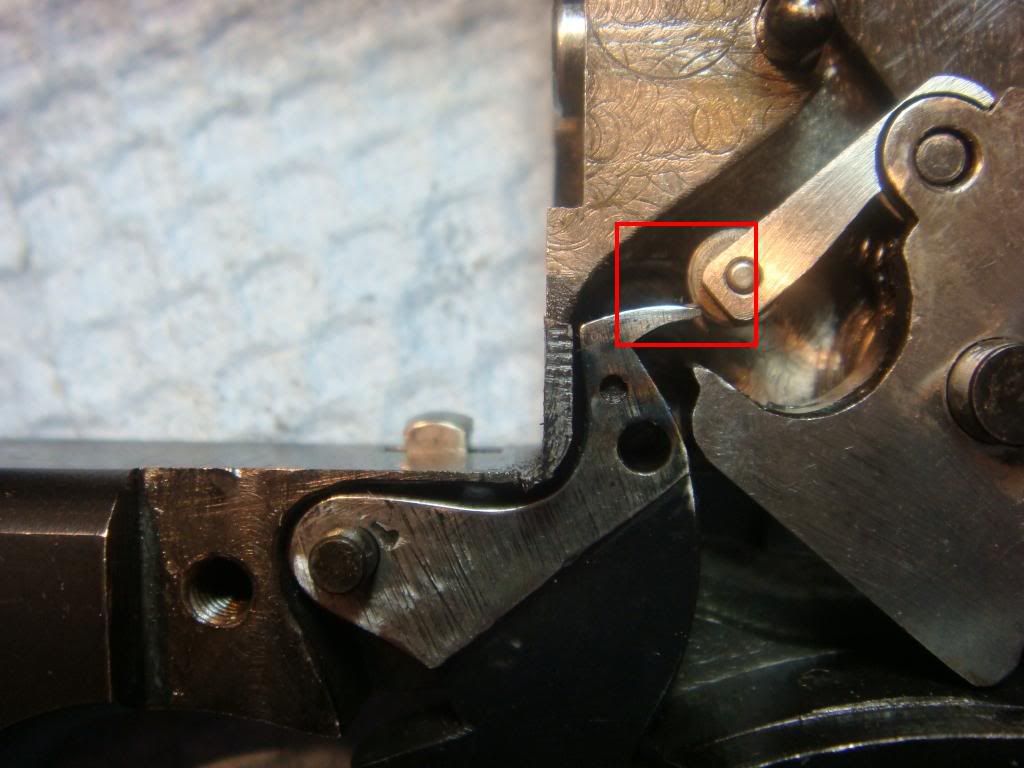

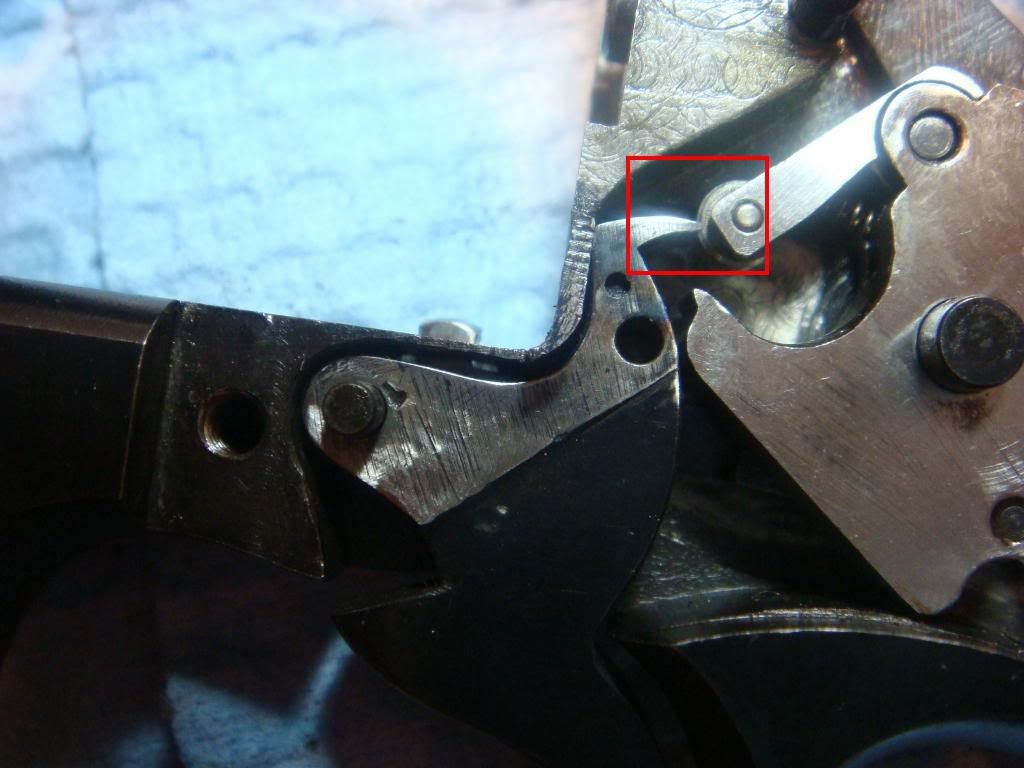

We do one of the standard tests of strut let out. Remove everything but the hammer and trigger. Put the trigger in the cocking notch:

And then move forward to exactly the release point:

Now bring it up til it as close as possible to the strut. On a stock gun they should just *barely* miss each other. This means that DA will release in about the same place (so timing will work out) and that the strut won't hit the sear on as the hammer falls. As you can see: it does hit it for the Sherman gun:

Which is ok, since it just flows around it:

Here's the same test on the Huntington 41mag python. As you can see the strut isn't quite let out enough. Finding the edge of the cocking notch:

Lowering the hammer: there's still a gap at the closest point:

The only other difference on the hammer I noticed is that the edge of it's face was filed down: a stock hammer (left) has a slight ridge:

Places that were polished

In addition to the mainspring, he also polished side plate where it touches the trigger:

And, it seems did some polishing on the frame (but perhaps that's just wear?) He didn't break the edge of the hand window, however:

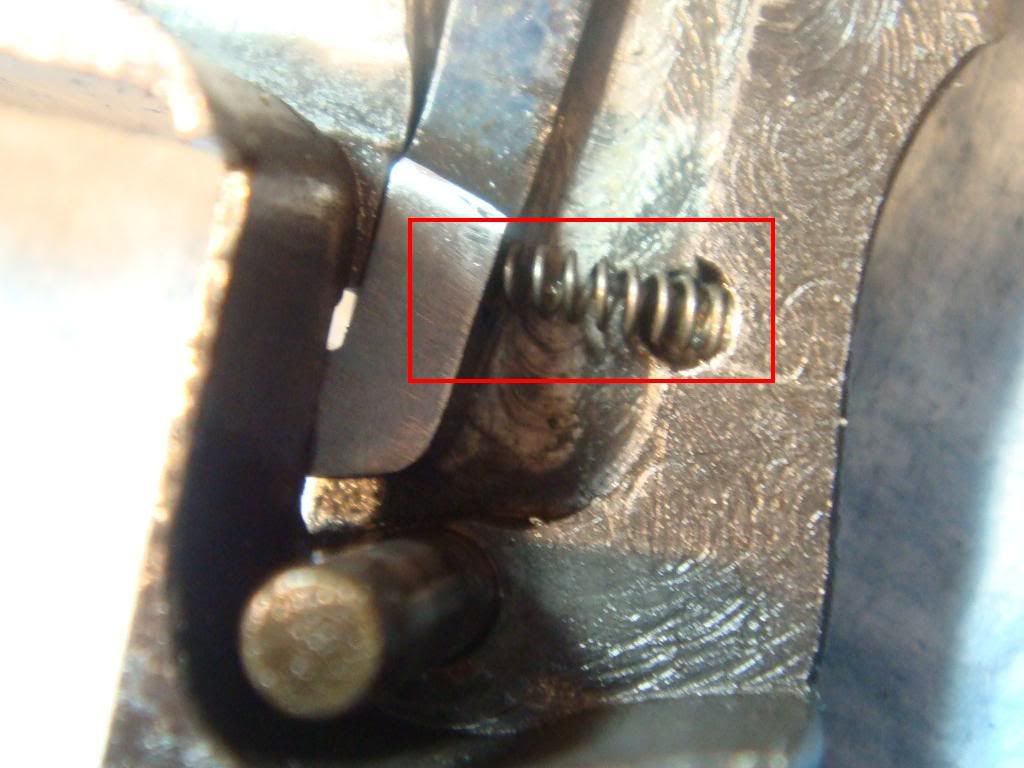

And he's swapped the colt bolt spring for the one used by all the cool kids:

But, interesting, other often polished places weren't. For example: the edge of the rebound:

And the front edge of the hand:

Both of these get pushed with much pressure, so smoothing them is a usual thing.

In addition, the cylinder is somewhat sluggish when you spin it:

This is often easily fixed, so I'm a bit surprised. (Though, as was pointed out to me by dfariswheel, the older colts were designed to have a smooth, but less freely turning cylinder than the later ones).

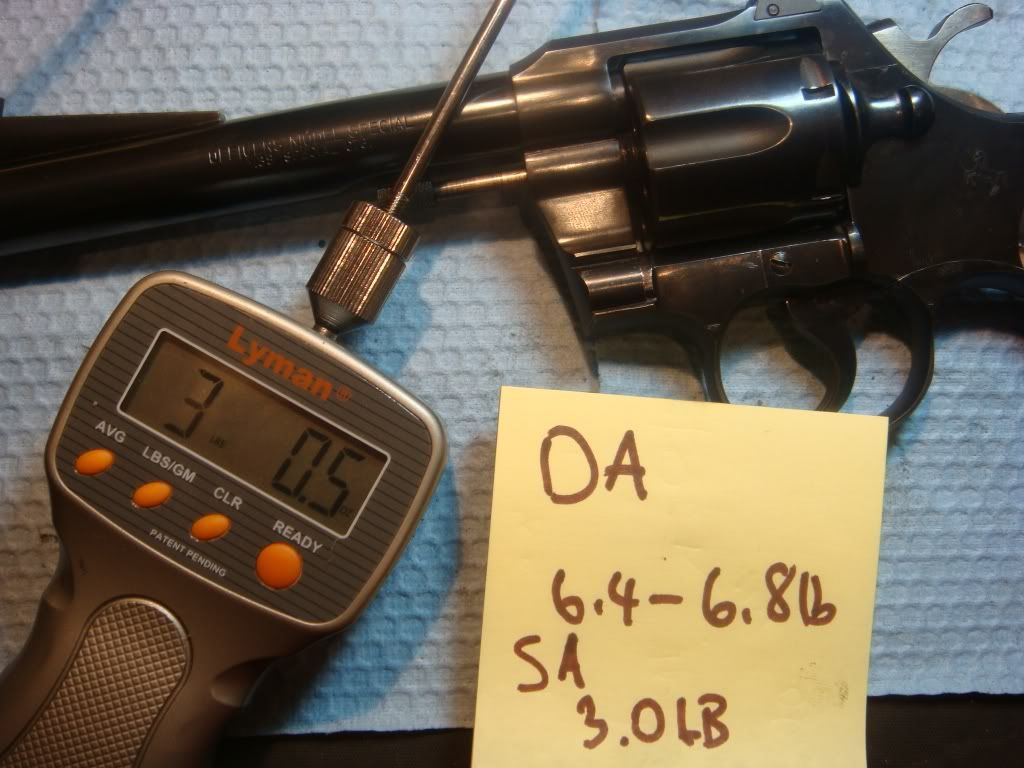

In the end we have a DA of around 6.5 lbs and a SA pull of about 3lbs.

A bunch of claims were made about 4 to 5lbs Sherman actions. At least for this gun, that is not the case: it's a consistent 6 1/2 lbs. We don't know the work order for this gun, so don't know if this is one of the bleeding edge Sherman actions, so it may be that this is high for what he does. Nicely, however, it doesn't seem to matter if the cylinder is open or closed. Getting that state is not easy.

There were also claims about him eliminating SA. This isn't the case, and it's a decently low number.

The strut dimensions on a preschoolers drawing:

Now, to really bury the lede, we only consider whether using the roller bearing is worth it. I'm not sure, to be honest.

It worked well enough that Sherman did it for a while as did, apparently, cylinder and slide.

It had some sort of issues since they both stopped doing it (for reasons I do not know).

As for it's effect: compared to a curved sear trigger with a *well adjusted* hammer strut, I think the main thing is that the roller bearing makes the last little bit of the pull slightly smoother and w/o the slight drag you can feel. Quantitatively, I don't know what the actual difference is: I need to rig something up where I can measure the last 1/4th of the pull weight.

One caveat for this particular gun: the mainspring isn't very light, so it may be that the magical benefits are hidden. (Its around 7lbs rather than 5 or 4.)

Further, for a non curved trigger, it may be that the roller bearing's benefits are greater (I'd bet on this) since there will be much more pressure at the end, where the stacking starts. More pressure = more effect from friction. It may be that this is an easy thing to do if you don't want to do the major surgery of changing the shape of the trigger sear. I'll test that out, hopefully within a couple weeks at most.

The roller bearing may be worse in terms of reliability: a small piece that has to turn freely can get gummed up. Or possibly break. This could be why they stopped offering it.

In any case, I do really like the feel of the action on this gun. So since all the work was done, I'll be shooting it alot. After putting the Fishpaw grips in the safe, though, where they will be worth more than some number of the guns.

And there you have it!

No comments:

Post a Comment