I've seen various references to longer firing pins, titanium firing pins, and otherwise weirdo modifications. It always seemed pretty exotic and not something you'd ever run into in real life, but it turns out that making such things is actually fairly simple.

I just got an Emco (not Enco! It's Austrian, not Chinese) Compact 5 bench lathe on ebay, so this seemed like a good project to try.

It's right before bed, so results were "OK", but presumably with a bit more focus they will turn out the way they should.

One great result is that the compact 5 is a fantastic lathe. It must weigh less than 80 lbs, but despite not being anchored to anything (yet) and not being leveled (yet) or any of the things a reasonable adult would do, if I cranked the RPMs high and used carbide it would cut the metal I have like butter even on fairly heavy cuts. This thing is awesome. I think I can actually bore out cylinders on it; it's certainly possible to make the bushings that fix endshake.

Here's the lathe, with the steel rod, a carbide cutter, a poor man's digital readout (which I took off) and an A2Z quick change tool holder which I have mixed feelings about:

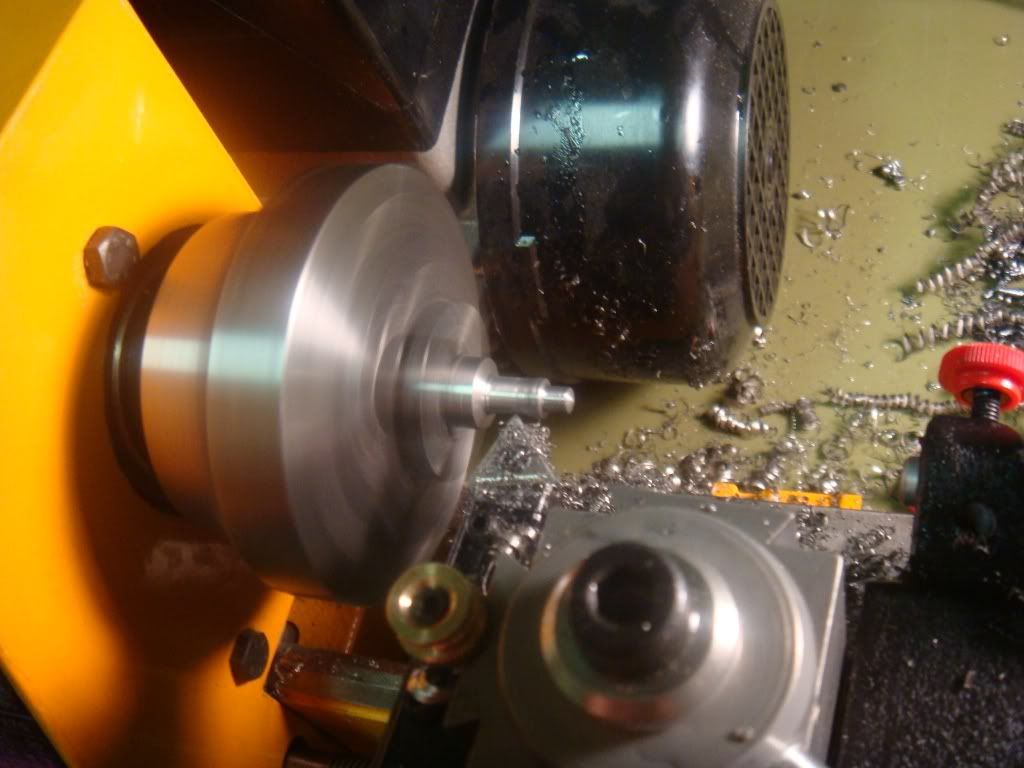

Close up: about to start cutting:

We turn the overall rod down to the highest spot of a pin. Here's the start:

And you can see we take a fairly heavy cut, especially for such a small lathe:

We then do the rear of the FP (if we did the front first it'd be hard to hold

when we flipped around):

We then rough cut the front a bit, and part it off:

And then apparently forget to take pictures when we flipped it around and did

the narrowest part. So here's the final result:

Longer than than a normal FP, which is where we are aiming:

You can make them as long as you like, obviously. Or use a different material. The one issue w/ the compact 5 is that the units seem to be mm, which I refused to use, which made the cuts somewhat haphazard. I'm going to put a simple digital readout on it to eliminate this issue. And pay more attention next time so the pin looks exactly right.

It's a fun project for a small lathe!

No comments:

Post a Comment