It's been a while since I opened a python side plate, which at my age means I'm just about to forget everything. So, to counter that my dad and I went through a 2.5 ported python has that someone went through some trouble for to make into a very (very) nice carry gun with a great trigger and excellent porting.

Here's what we have to work with:

As you can see, it has an interesting matte silver finish which I am guessing is "armalloy". It's very tough, easy to clean.

He has a pair of Harret grips on it that he likes. (The roughness of them tears up my hands after a few hundred rounds.) Removing the grips, you can see the INS (inspection) stamp which they did in the early days.

Here's the porting; as you can see, I didn't clean it after the range, and a bunch of lead got shot out of it:

This porting is great: the barrel barely moves and recoil is tamed, even with hot 357 loads. I've been told that such elongated ports were done w/ an EDM machine. They have them on ebay for a few thousand or less...

For anyone thinking about porting theory, here's the approximate angle they used:

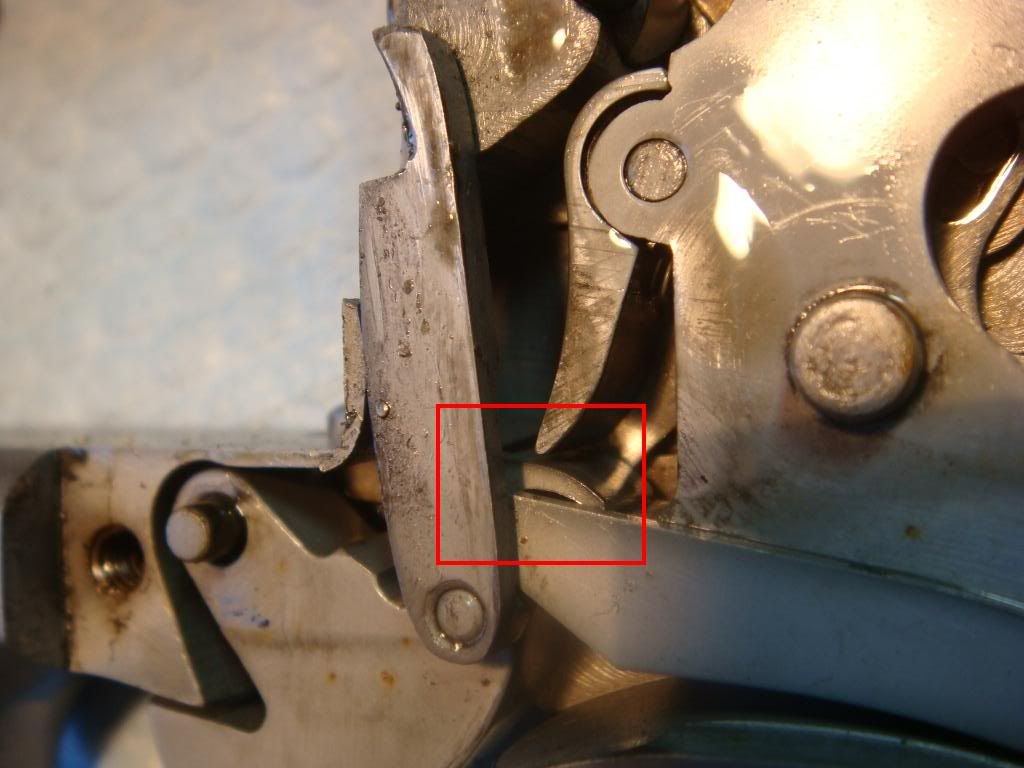

Finally, here's the internals. A bit hard to tell, but they plated just about *everything* (pop quiz to be answered in a couple of screens: if you want to protect against lawsuits, what wouldn't you plate?)

Now, why is the action so good? I kept claiming it was likely the standard reason and, fortunately for my street cred with dad, this was indeed the case. You can just make out the Tedford-style curved sear on the trigger:

As we all know now that is the standard way to remove stacking in a colt by making the pressure more uniform as you pull the trigger.

So, cool, we're now in a rush to get to the trigger. As part of this, we take off the mainspring and notice that they thinned out the bottom leg --- this is one way to weaken the mainspring. The modified mainspring has a rectangle, a stock one does not:

Often people just use a grinder freehand, but this is uniform enough that I'm thinking they either used a diamond wheel /carbide grinding setup with plate supports or possibly a milling machine.

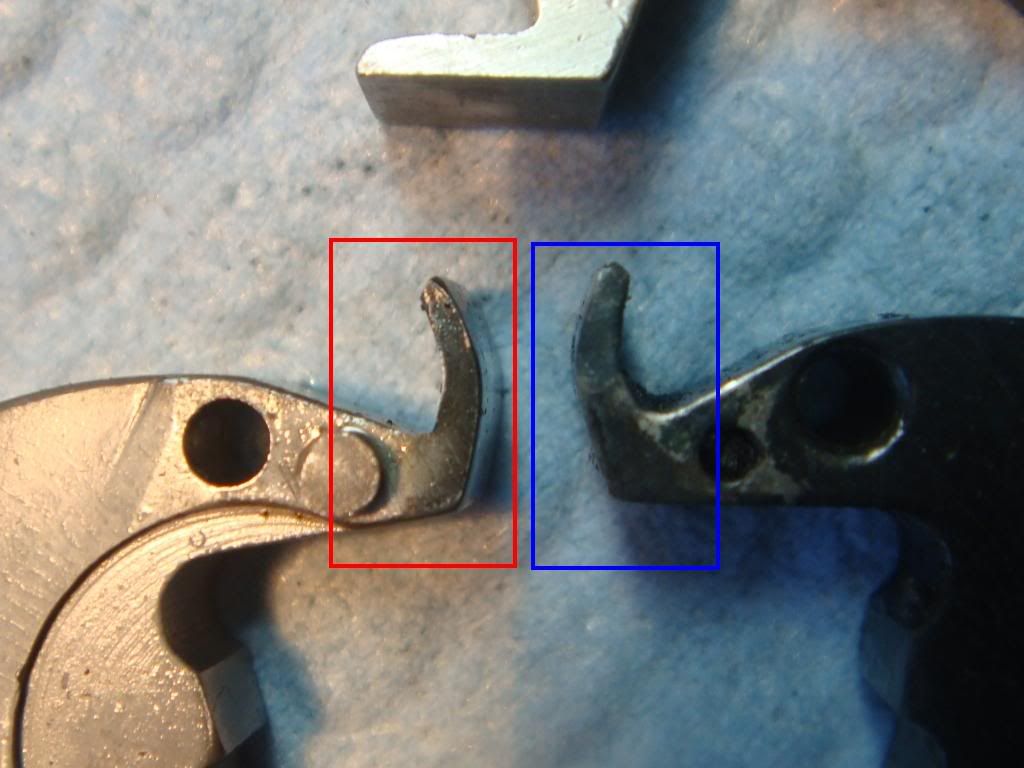

I need to measure width, but here's a qualitative view of how much they took off, modified on left, stock on right:

Ok, so the trigger. The 2.5 trigger is on the left, a trigger done by Frank Glenn on the right, and stock is above them both. It looks like the 2.5 trigger is slightly thinner, perhaps they beat it more after heating it with a torch. Frank pointed out that some people thin the sear with a file and then bend with pliers, so this might be the cause of thinness:

Closer view, 2.5 on left, Glenn trigger on right:

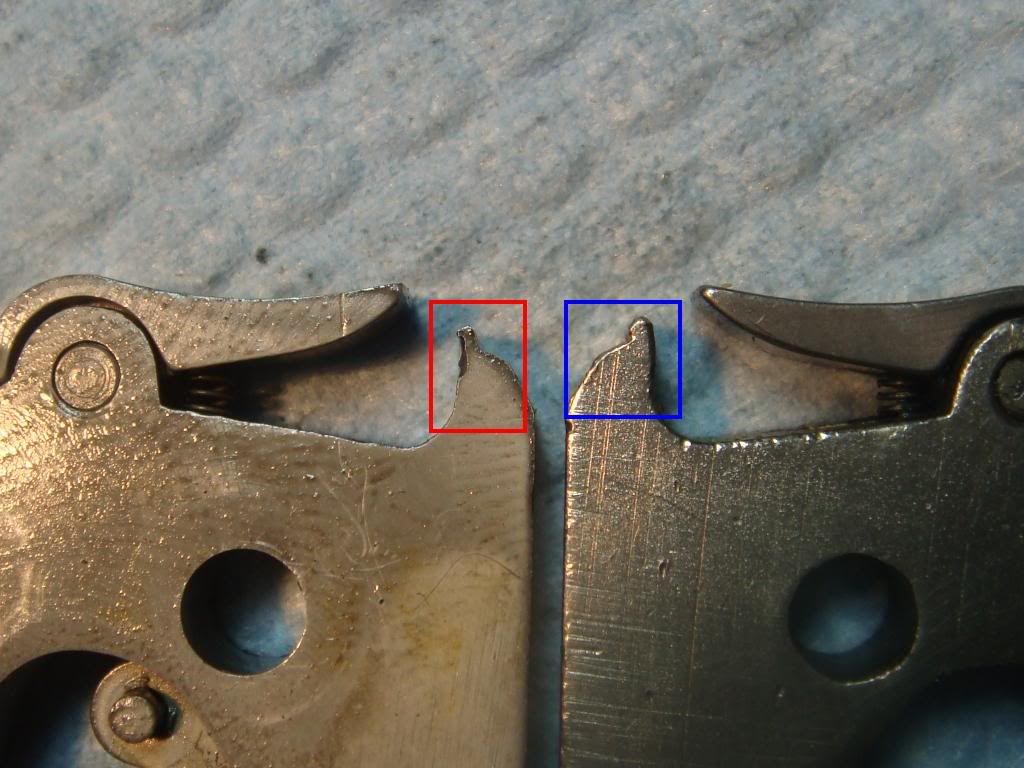

The downside of curving a trigger is that it makes the single action suck. So a common thing is to file out the cocking notch in the hammer

Before we go further, let's reaffirm basic survival precepts: DO NOT MESS WITH THE COCKING NOTCH ON A STOCK TRIGGERS! It's unnecessary and BAD. Curving the sear changes the angle enough that we don't have much choice, unless we want to keep a heavy, creeping SA after doing a DA action job.

So, w/o further drama, here's the modified hammer (left) compared to stock (right). You can see from the rectangles that they've filed away a small amount of material in absolute terms, but a fairly enthusiastic amount in terms of what's in the cocking notch:

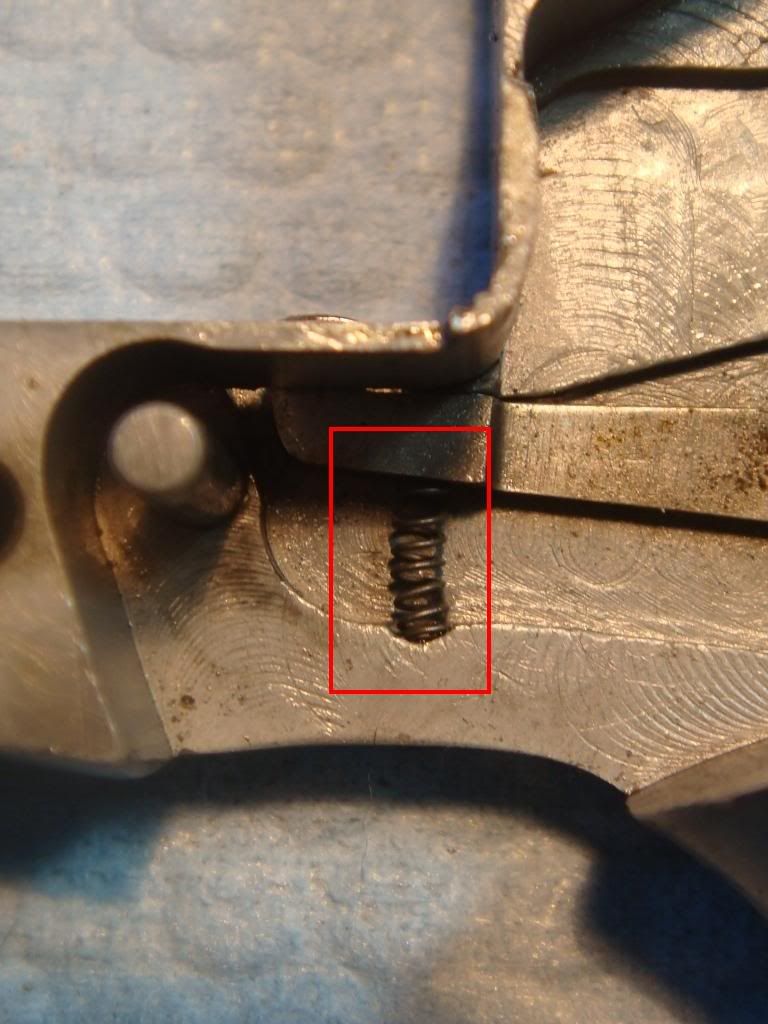

As we've come to expect, they replaced the bolt spring, so that the bolt presses less hard against the cylinder. I don't recognize the spring they used --- it's not the one I was shown to swap :):

Here's the parts they plated. Almost everything:

Now, if you were worried about a lawsuit, what do you never plate? Yeah, indeed the safety mechanisms:

For what it's worth, Harrett's uses a bushing in the grip (presumably so it

doesn't oval out under recoil making the grips loose):

The gun is nice to shoot. One reason is that it looks like someone cut the front sight thinner. The one on the 2.5 is .098", the ones on stock pythons I had laying around is .124". I have to really recommend using thinner front sights. Glenn made me a custom fiber optic front that makes a big difference, in part b/c of how thin it is:

And there you have it.

To summarize:

- Classic, simple action job. The obvious tricks they played: a Tedford style curved sear trigger, reform the hammer notch, cut material off the lower mainspring leg and polish its end, and replace the bolt spring.

- Great porting.

- Thin the front sight.

- Not much else (that I noticed).

Really nice, functional carry gun. Time to buy the porting tooling I've been

putting off getting!

Yes, Mag-na-port uses EDM to form their ports. The following link is to Larry Kelly's US patent on the process.

ReplyDeletehttp://www.google.com/patents?id=8757AAAAEBAJ&printsec=abstract&zoom=4#v=onepage&q=&f=false

Speaking of EDM, I suspect that the Colt triggers could be fabricated by EDM. You could make a little business out of manufacturing replacement curved sear triggers.

Thanks for the patent! Very interesting that you can patent such a thing.

ReplyDeleteI don't have an EDM machine, but perhaps that should change. I was hoping to use a CNC mill to make bolts, rebounds, and hands. It's been pretty easy to CNC up firing pins. Doing a trigger itself would be a nice addition.