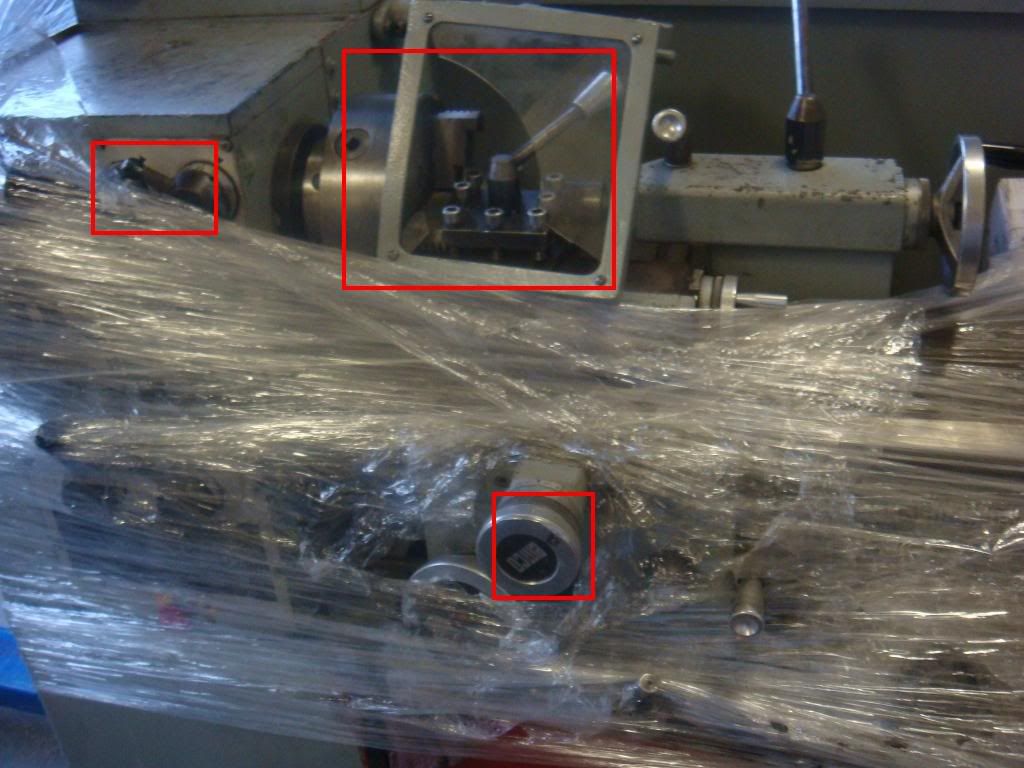

I was going over a m357 I'd tuned for my dad, correcting some issues. I replaced the rear sight with one of the very nice kensights (clone of the elliason) available from brownells and, since the sight was off, just to be thorough I went to take off the firing pin plate to clean out the recess.

As my dad watched, I had an incredibly hard time getting the firing pin plate off. And then it was just about impossible to get it back on.

This, of course, should never happen. A child with a punch can get the plate off and on --- there's really nothing tricky, nothing to go wrong. If you see anyone having a hard time with it, they really must not know what they are doing.

When I took the pin and spring out the plate would go in w/o any issue.

Any guesses for what the deal was? It was kind of amusing. Kuhnhausen has a warning about such things, but I always skip it thinking "irrelevant information."

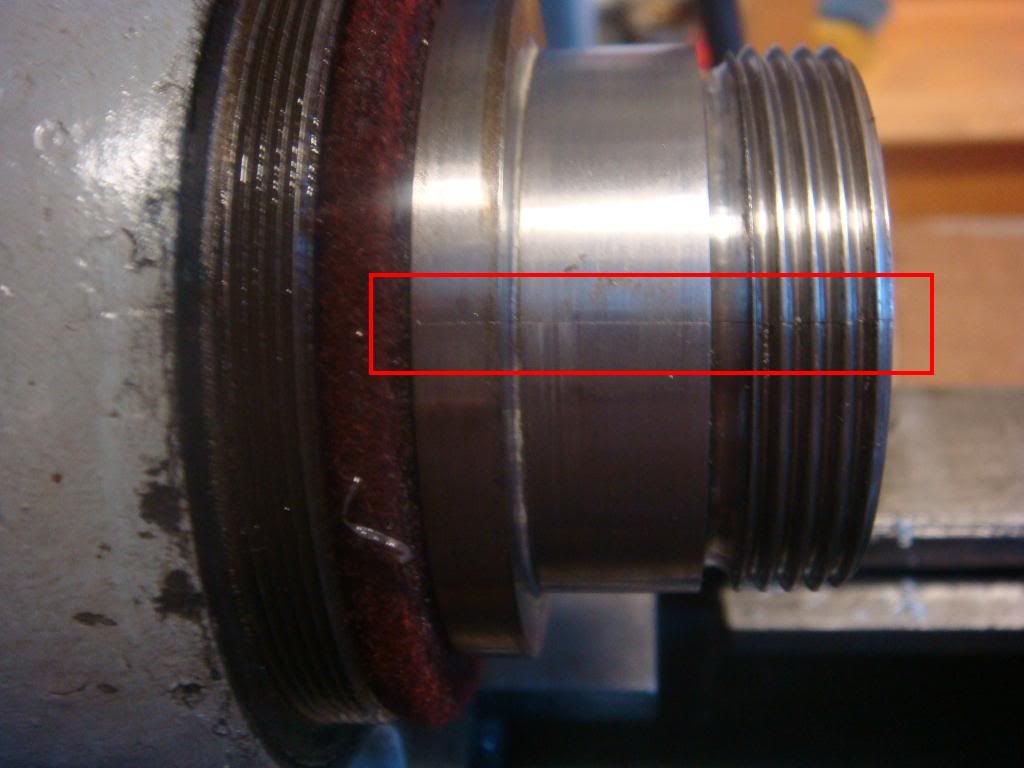

One of the other issues was that when reblueing, the person couldn't be bothered to take the bolt off, and essentially sheared the end down to a flat with the buffer. This seemed to cause it to come loose under fire.

So, after having all the difficulty, it eventually dawned on me that the only real reason it could be hard to get in w/ the firing pin in place but not without it removed was that the spring must not be compressing enough. Well how could that be? Oh, did they ... ? Yes they did!

Answer below after a few line feeds :)

Here's a stock firing pin spring and bolt screw on the left, and the spring we have in place and the sheared bolt screw on the right: