So, among the many things wrong w/ an Emco V13 engine lathe I picked up (not it's fault), the chuck had been sorely abused and required serious cranking to turn the key towards the end. This is a short post on fixing it.

I'd not seen something written up (though I'm sure there has been, many times). And it's definitely not rocket science. However, sometimes it's useful to realize something is not rocket science so you actually do it. In this case fixing the problem made a big difference, though it still remains to a slight degree.

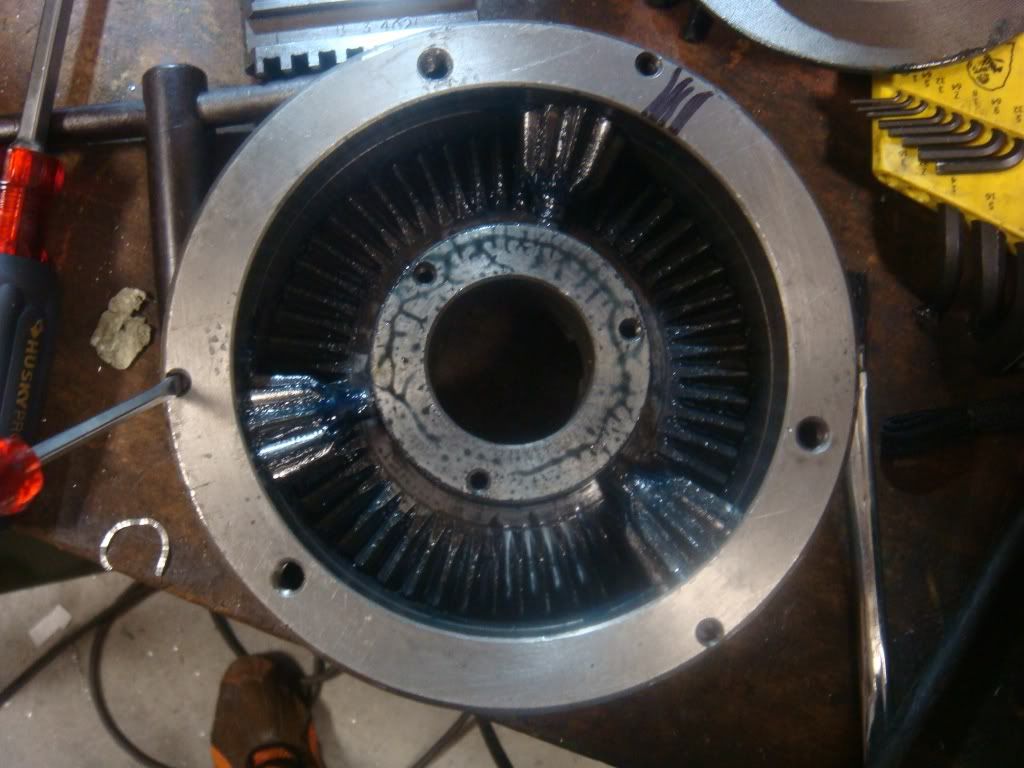

Here's the chuck. V13's have a D1-4 mount:

While it's not rocket science you DEFINITELY want to do witness marks to keep track of the orientation of the backplate to chuck when you take it off. I used marker, but that's stupid, given how easy it is for solvent to take it off. I'd scratch something instead.

After removing the backplate and its mark we get:

And you can see how turning the chuck key will make the internals turn as well.

Removing the interior plate we see the problem: the part that the jaws ride in looks like it was viciously stabbed with a hardened pin. Additionally, someone has generally added various dents. The spiraling avenues have to be clear, or the chuck jaws are going to get bound up, as they have been:

After filing flat w/ a medium mill file:

I then ruined the end of an India stone a bit trying to get into the channels:

We then put things back after putting moly grease on everything:

Now, here's the mildly tricky part: how to put the jaws back? Well, of course, they are marked (or you marked them) as to which groove they should go into. But which to put in first? Turns out that you start with 1 (everyone knows this but I didn't). You do so by turning the chuck key until you can see the beginning of the spiral in the 1 slot:

You slide in 1. Then turn the key some more til you see the beginning of the spiral in slot 2, and put that jaw in:

And finally, you guessed it: 3:

End result is way better than when we started, though there is some slight binding remaining. The file work is way easier than what we'd need for a colt (though the narrow grooves in the spiral are a pain in the ass to get into). And we got to clean and lube everything as well.

One open question is whether I should have skimmed the backplate to try to true it up carefully. I figured I'd leave things no worse than when I started, but given that it was disassembled might have been worth doing?

No comments:

Post a Comment