OK, I know I am about 100 years late to this particular party, but I have to say that fly cutters are freaking awesome! I'd always heard about them but just throught "WTF do I need another tool for?" Turns out that was pretty stupid.

The phrase you need to remember is "poor man's surface grinder."

Once you figure out how to grind the tool correctly you'll have fun. I've been squaring up aluminum for hours for no particular reason.

Pixels beat letters, so let's get to it.

I recently picked up an emcomat 8.4 mill/lathe combination. Generally I have a low opinion of combination machines (fish nor fowl) but Emco has a wonderful reputation for high Austrian quality and this machine lived up to it. It's a pretty sturdy machine (400lb?) for its size, and like the other emco's I've used cuts way above its weight. As a nice touch, the previous owner hand cut 10 quick change tool holders:

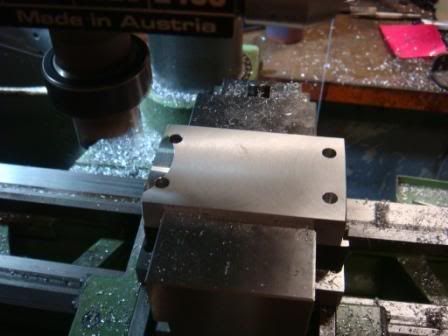

We have a rough piece of aluminum that we start making a cut on:

And that works out so well we continue:

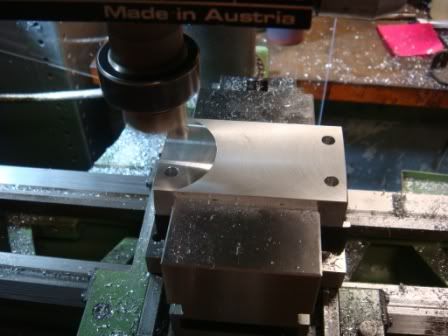

More!

More!

Just a little more!

And done. As you can see, fly cutter is just a lathe bit (with enough rake) in a tool holder. Only difference is that you spin the bit rather than the piece:

No comments:

Post a Comment