So besides being a weirdo caliber, the 22jgr OMS dissected before had numerous common issues: (1) bolt pickup wasn't instant, so the cylinder stuck, (2) timing was off (bolt dropped too soon), and (3) lower hand was too short so cylinder didn't rotate entirely. This post is about fixing them.

Note: contents are for amusement only! If you do these things to your colt you'll break it. No guarantees that I did things right to mine --- no one gives me money to work on their colts. If you see something wrong point it out so it doesn't happen again!

Fixing delayed bolt pickup

In any case, since we have to get the bolt pickup right before we can fix the other two problems we get to it first.

As soon as we pull the hammer back the bolt should start dropping *instantly*. If it's delayed it can bind up in the cylinder --- if you don't check for this it's easy to think the top hand is too long and file that. This is ,of course. stupid, especially since you can't put the metal back.

So we always look for bolt pickup.

Hammer at rest:

Hammer pulled back as far as we can before the bolt moves at all:

Not so impressive. Easy to spot, which is good at least.

For a correctly fit bolt cam and a correctly fit rebound cam, delayed pickup is usually because the rebound is too low --- i.e., low enough that its cam is not in contact w/ the bolts cam. If there is a gap between the bolt cam and rebound cam you cannot have instant movement since the space has to close before the bolt will move at all. (I didn't take a photo, but should have.)

The solution is to bend the rebound higher til it's in contact with the bolt.

Now unfortunately, the bolt and rebound cam in this particular OMS do not look well fit. The rebound cam in particular is very small. However, I don't have many parts, so first am going to try to see if adjusting these will make them work. It won't be the first time that an E-frame revolver has behaved correctly with a rebound cam that seems too puny to do anything.

The shop manual recommends hitting the rebound w/ a hammer to adjust the rebound higher or lower, but for minor adjustments I use a tool made by Frank Glenn to try to bend it in situ. It seems (for me) to allow more control. We first try do minor adjustments; major can always come next.

Here's the tool: a bent allen wrench:

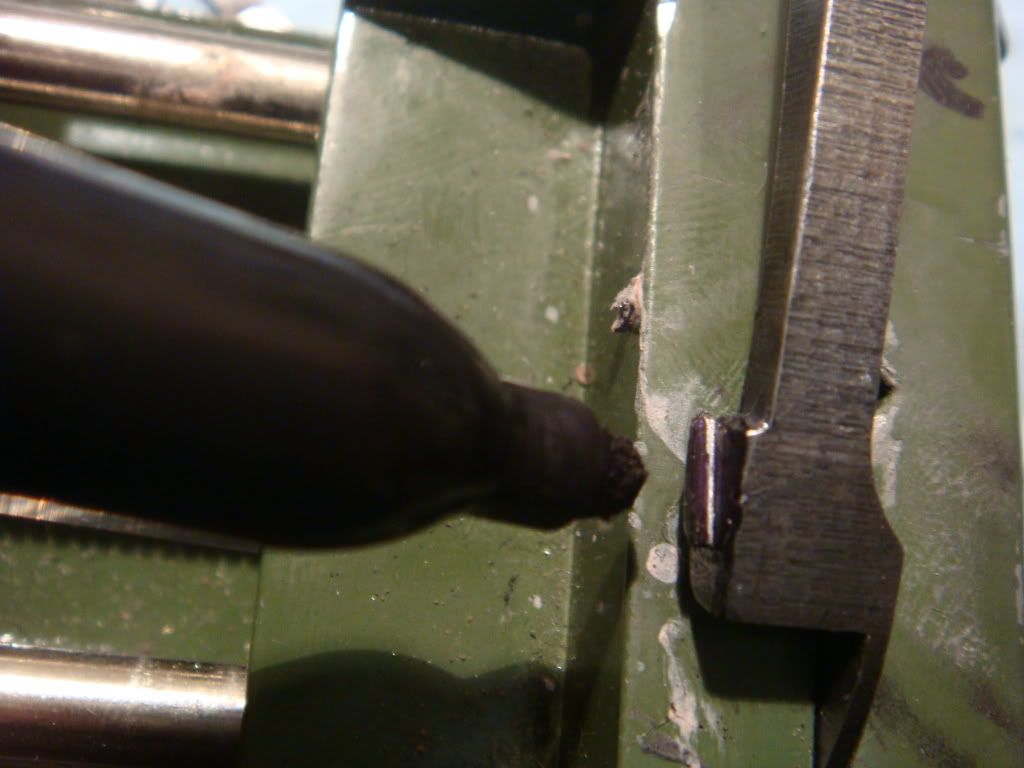

And here's how things get bent: remove hand and spring, push rebound against hammer pin:

Not surprisingly we are still very far from the rebound touching. We need to make larger adjustments, so go to a variation on the shop manual's method (suggested but not endorsed as the best way by Grant C): place the rebound across the open jaws of a vise so it's supported near the cam and the end and hit near the cam w/ a ball peen hammer:

After doing this, it seems that the pickup isn't a whole lot better. Given how the rebound looks, the likely explanation is that the cam has been filed too small to be in contact with the bolt.

Here's a close up of the rebound cam for the installed rebound (top) and one for a takeoff from an I-frame (bottom):

You can see the significant difference in the cam sizes.

We now try swapping the rebound to see if that fixes things. The parts situation being what it is I usually try rebounds from my stock of takeoffs --- often one of these will work. If that fails, I'll reevaluate the situation and, if necessary, then fit a rare, new, rebound. Swapping rebounds doesn't hurt anything, since we're not removing metal from anything, so is a nice safe thing to try when there is ambiguity.

After going through 4-5 rebounds, we get one that actually fits fairly well --- slightly high, but the bolt is definitely in contact.

Since it's high but otherwise seems to function well (no hammer bounce, etc) we fix it by (you guessed it) hitting it to bend it lower. We flip it the other way on the open jaws of a vise and hit it firmly above the cam area:

We do this a few times to lower it, but then stop to re-evaluate since, as you can see from the photo it's already pretty close to the frame:

Now at this point we enter the NOT RECOMMENDED EVER phase of our adventure.

Our problem: E frame rebounds (and bolts) are not made anymore. So people (including the factory) fit I-frame rebounds and bolts for them. This is well and good. Except that it appears that it's no unheard of that you have to do some modifications to use the I-frame part in the E-frame that you would NEVER EVER DO to fit an I-frame rebound into an I-frame revolver.

In particular, the cam can be too high. In extreme situations according to Grant C you may have to file the top off the cam *SLIGHTLY* to make it low enough for the bolt to reset. (No guarantees that this is one of those situations!)

However, for most situations where you think you have to do this, you do not and you should think about things more. The most common mistake w/ colts is that people file on things that are symptoms rather than causes --- jacking up the rebound cam is a prime example of a cliched mistake that the clueless do.

In fact this is the first time I've ever filed the top of a cam out of about 30-40 colts. I know that in the past I've ruined two rebounds because I refused to touch the cam --- which led to the questions above.

OK: so we hate to touch the cam, so take things slow. Set it up so it's level in a small vise:

Mark where we want to file with a sharpie so we can ensure it's even and not take too much off:

And then take just enough strokes (3) to remove the sharpie ink:

And, that is now enough! Rebound fits. Bolt pickup is instant. We did not have to use a new rebound.

Now for this gun it might have been possible to take more off the front of the rebound (where it touches the hand) or to bend it lower. It was low enough already that I didn't do this, but someone that is an expert might have. So don't judge what to do by my actions!

Fixing timing.

Ok, next problem is getting the bolt to drop in the middle of the cylinder groove (lede).

Our test here is to slowly cock the hammer and see where the bolt drops.

We first start pulling the hammer: bolt clears cylinder correctly (since we just got this right above):

But, as promised, unfortunately drops right before the groove rather than inside towards the middle:

In fact from looking at the cylinder you can tell that the hand has been really out of time in the past since the turn line seems continuous.

As a second problem (which we'll do later) the hand is too short, so the hammer cocks before the bolt is in the notch. You can see the bolt slightly out of the notch here:

Turning the cylinder causes it to "click" into place.

As a check to see what's going on, we examine how the bolt is falling off the rebound cam (I got this from Frank Glenn, but I think the shop manual also shows it). Look from the back and slowly cock the hammer --- the bolt should drop off the front. A common problem is falling off the side. This will often cause the bolt to drop early.

Bolt and cam at rest:

Starting to cock -- -you can see the bolt going off to the side:

Falling off, on the side:

Hopefully this just means the angle of the bolt cam is wrong since that's easy to fix. We take the bolt out and hold the tang near the cam using round needlenose (real colt smiths use different tools, but we're low rent tonight):

And *SLIGHTLY* bend it so the cam is more towards the rebound.

Putting it back, it largely worked --- the bolt drops very close to the middle of the (very short E-frame) groove. (It may be slightly over, but we'll leave it for now):

It also falls off the front of the cam, which unfortunately I didn't take photos of.

Fixing too-short hand

The funny thing about colts is that to fix some things you remove amounts of metal measured in the hundredths, but to fix others you whack them *hard* with a hammer.

This is one of the latter moments.

So: hand was too short so couldn't rotate the cylinder far enough. We can use a new, rare hand. Or we can take the existing one, made from soft metal, and peen it with a hammer and dulled chisel to stretch it out.

It's late at night, so we hit it with a hammer. Of course.

Our surgical tools:

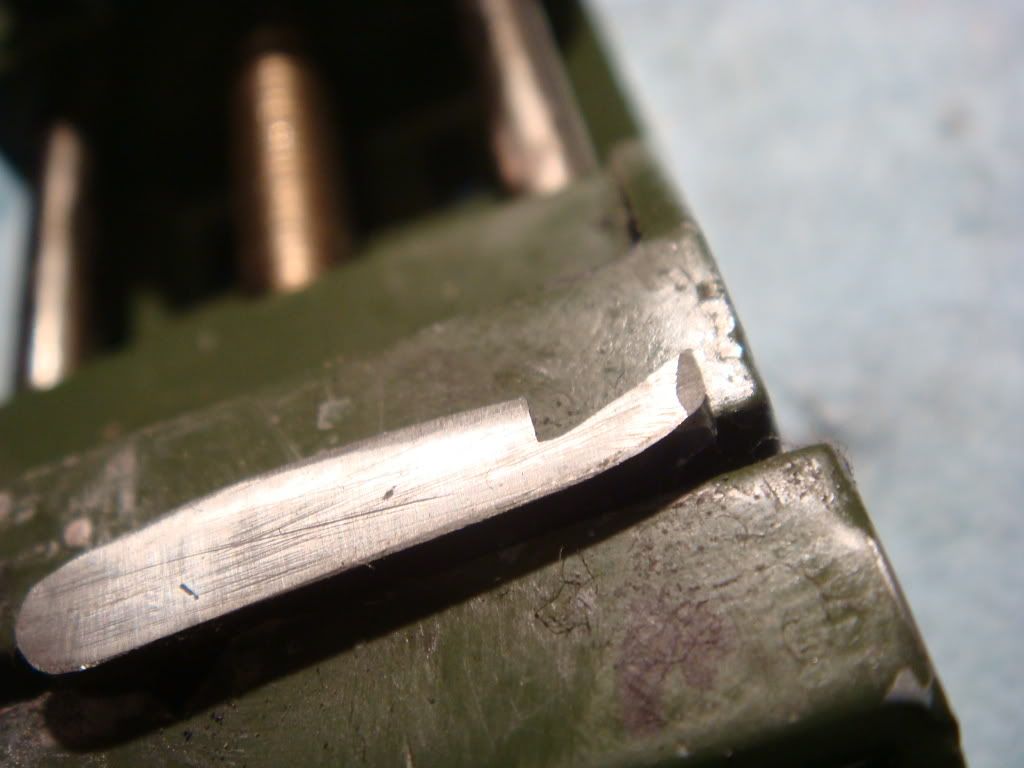

A close up of the hand before modification --- doesn't look like it's been peened before (two peenings = not recommended):

After about 10 hits (a few hits, check, a few hits, check) when it becomes long enough:

We try to keep the ridges even and uniform depth. Even so stress is not just applied in one place (you just broke the hand), uniform so we can file them out easily. In our case we have a couple deep cuts that a professional wouldn't get.

Often after peening the hand will curve --- if you don't fix this the gun's action is going to feel horrid. Here's the curve:

Which we fix by flipping it over and beating it the other way.

We now try to remove the scoring using an arkansas stone and file-backed 600 grit sandpaper:

Getting this:

We also curve the top of the hand a bit:

And polish the front to make things a bit smoother:

In general: our tension is that we want to smooth things out, but want to remove as little metal as possible. Less metal = looser. And too little metal = too bad, can't put it back.

After all the above we reassemble and check that things still work. The do, largely, though now you can notice the cylinder *slightly* binds in the same place as you rotate it freely. I won't fix this tonight, but note that the trigger pull w/ the cylinder open is a fairly constant 8.9lbs but with it closed ranges between 9.8lbs and 10.10lbs.

And there you have it. Time to soak the OMS in dunk-kit for a couple of days and then molylube and recheck it.

No comments:

Post a Comment