picked up two very similar OMMs recently. One was SA-only (by the factory from the looks of it) the other was a standard DA.

I stripped both down tonight so it's possible to compare them. The SA was clearly modified: the trigger sear curved, the hammer seat filed out in a groove and (I believe) the cocking notch modified. It looks very similar to how Frank Glenn does his stacking-elimination trigger jobs with the modifications that the sear is significantly shortened and the hammer strut is removed.

Enough chitchat, let's get to the porn! Note, the first five pictures are just set up. You can skip ahead to get to the money shots.

Two shots of the standard SA/DA action [notice the straight trigger sear]:

Three shots of the SA-only action, notice how the sear curves down, the seat has been filed into a pronounced groove, and the hammer only cocks halfway:

Removed from the pistol: SA trigger and hammer on the left vs the normal trigger and hammer on the right:

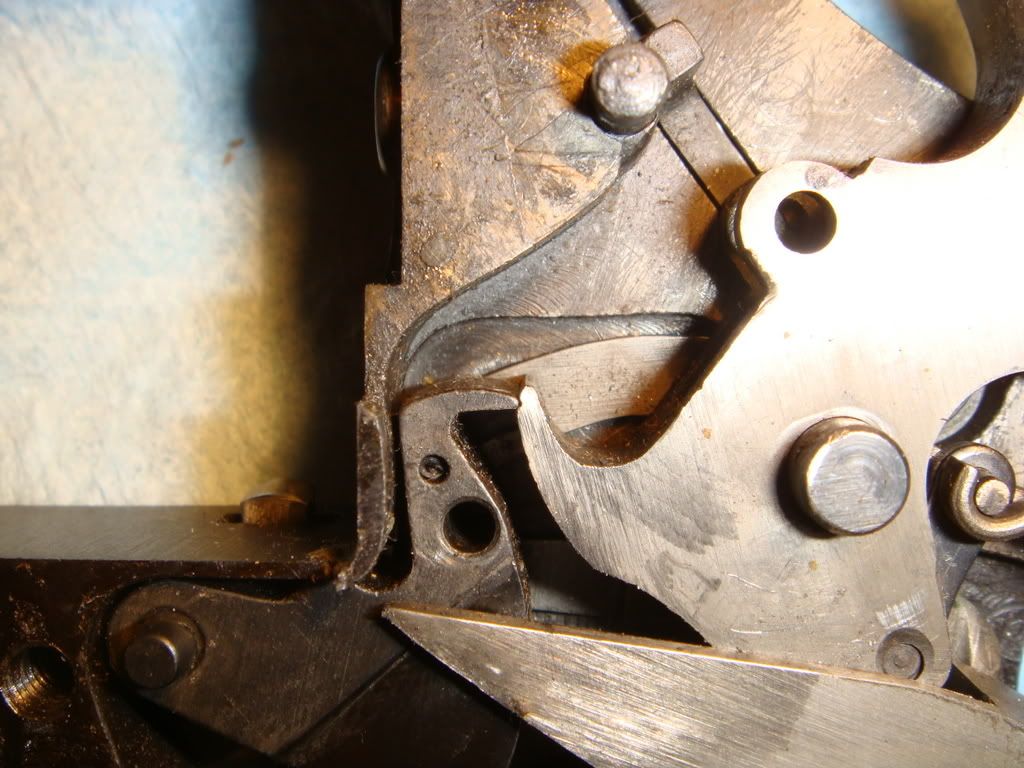

And a closer shot (SA left, normal right):

And just the hammer (SA left, normal right) --- notice the cocking notch was somewhat altered, just as you'd do w/ a trigger curved to eliminate stacking in order to get the SA down below 4.5lbs:

There is a screw stop for the hammer in the SA-only frame and a slot has been cut in the back of the SA-only hammer:

Normal frame on top, SA-only on bottom:

Close up of SA-only frame w/ screw:

Normal hammer on top, SA-only on bottom: look at the back of the hammer:

Apparently it was common on SA-only action jobs to remove material from the hammer so it would drop sooner --- these guns were for competition shooting and the theory was that you wanted ignition as soon as possible after pulling the trigger.

I should also take some photos of the trigger from the top --- it looked forged rather than welded. Or if they did weld it they reblued, which seems odd. This would suggest it was done by the factory, I believe. (According to Grant Cunningham colt would not ship these parts to external people.)

No comments:

Post a Comment